1. How to print on fabric?

Printing on fabric involves several key steps, each crucial to achieving a high-quality final product. The process can vary depending

on the printing technique used, but here's a general overview of the typical methods:

1. Choose the Printing Method

Screen Printing: Ideal for high-volume orders, this method involves creating a stencil (screen) and then using it to apply layers of

ink on the textile surface. It can be less economical for small runs due to its time-consuming setup, limited color options, reduced detail

capability, and environmental concerns.

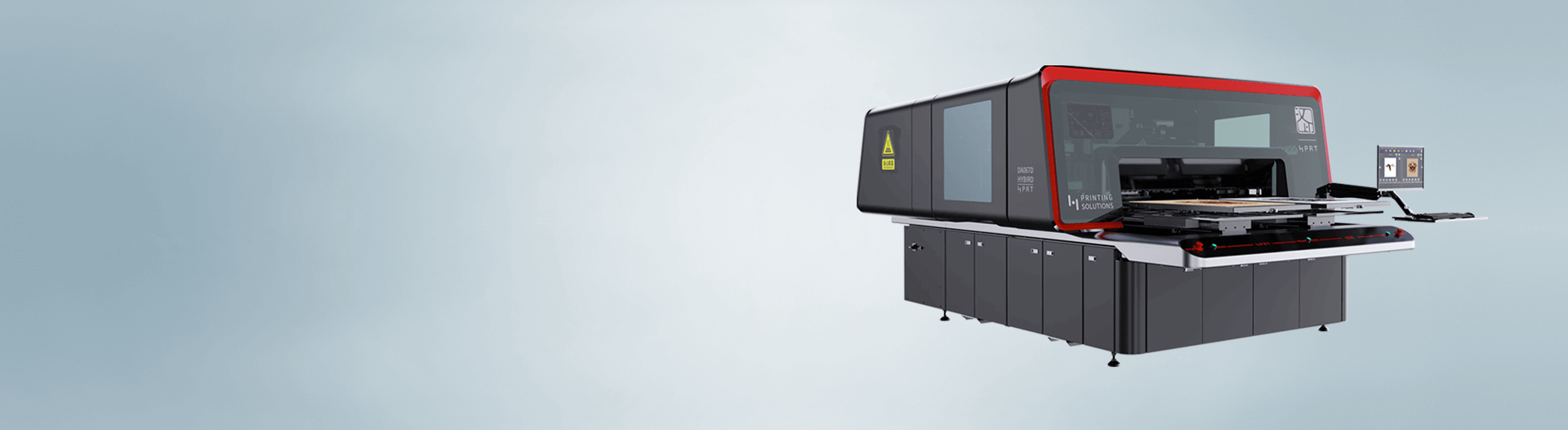

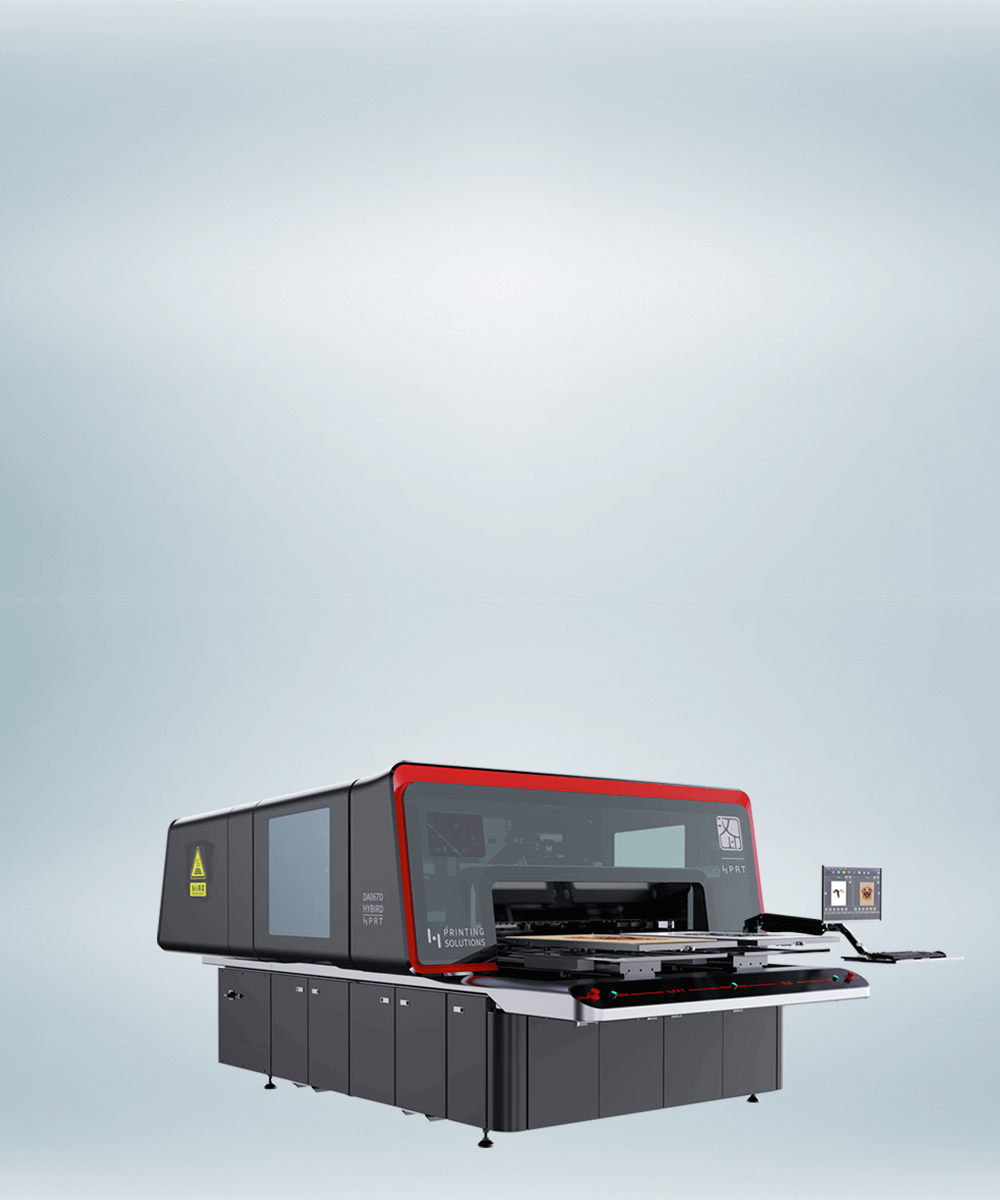

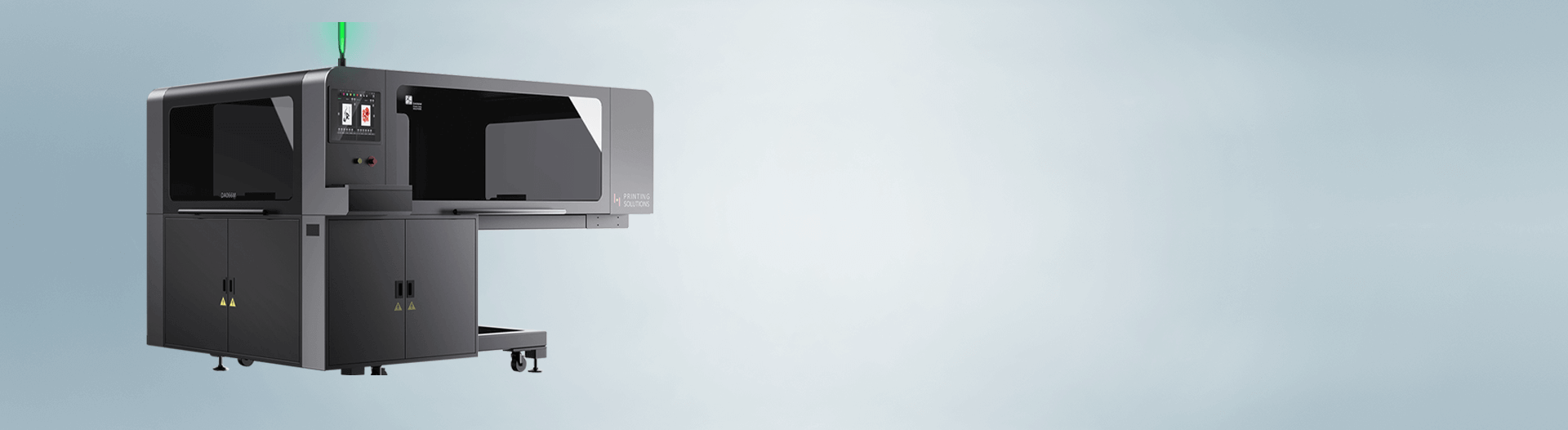

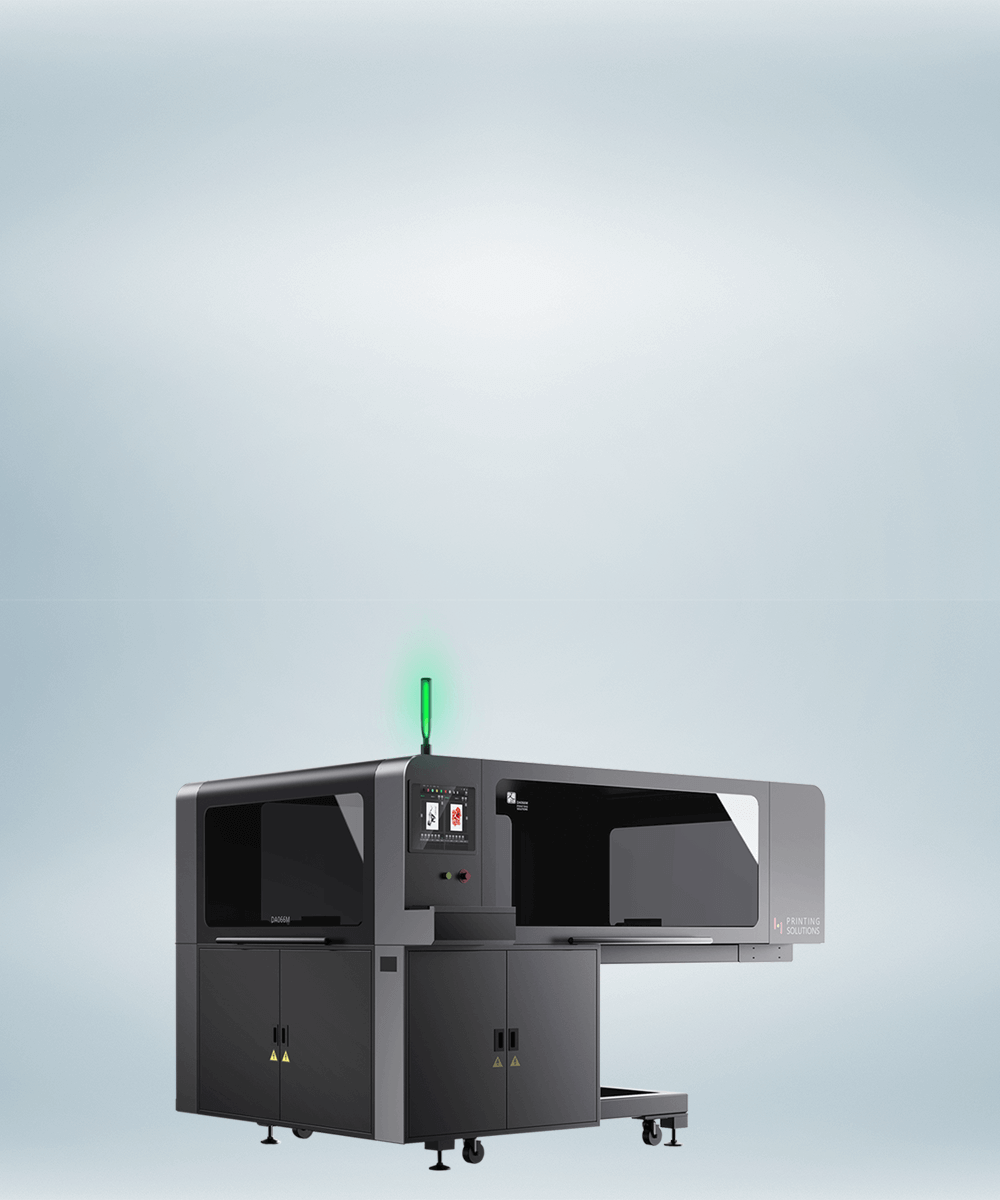

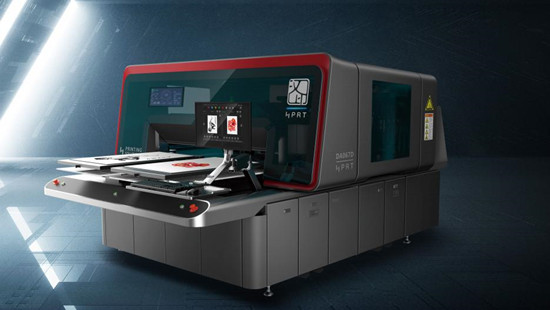

Digital Textile Printing (DTG): Best for intricate designs and small to medium batches, this method uses inkjet technology to print

designs directly onto the fabric.

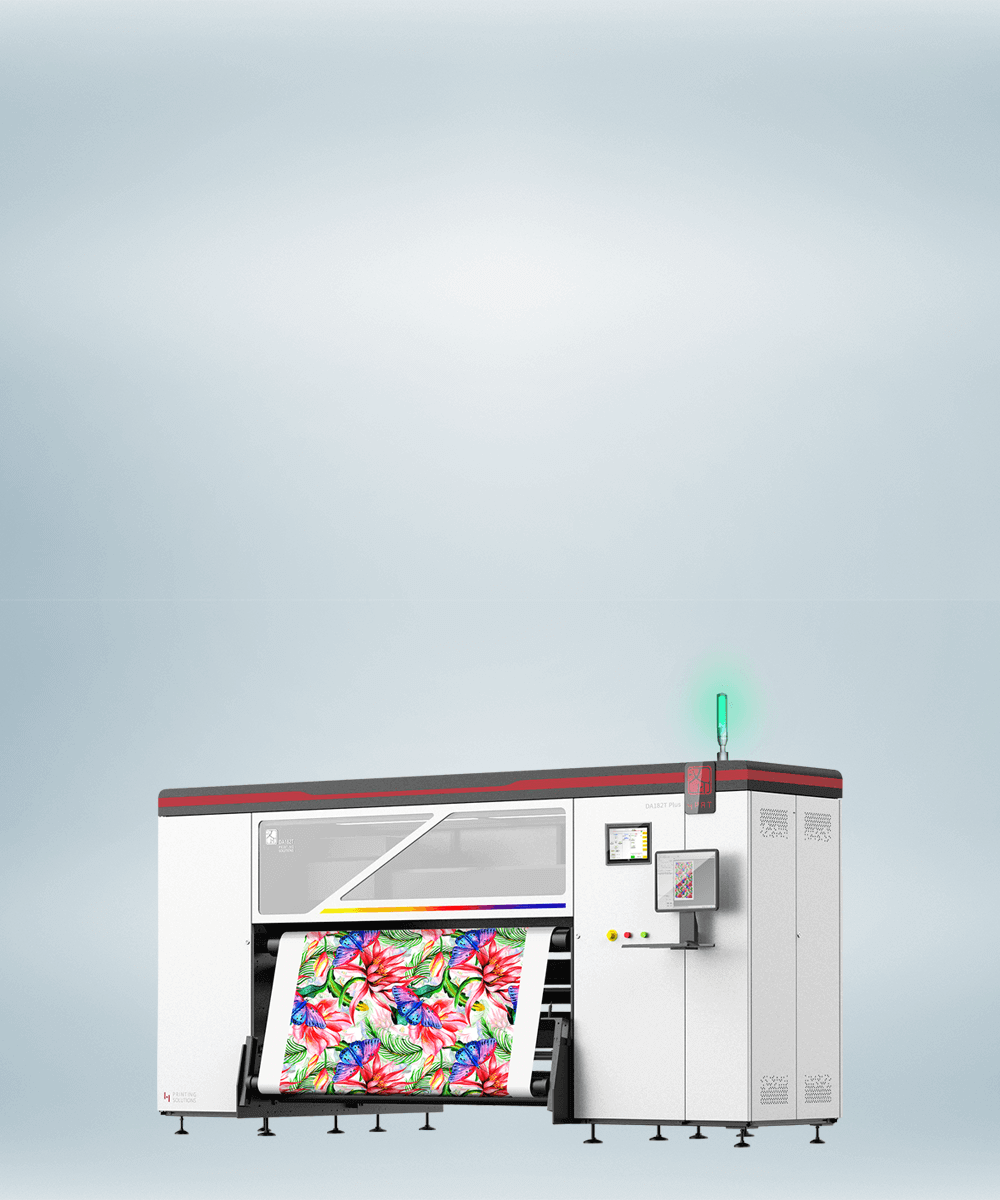

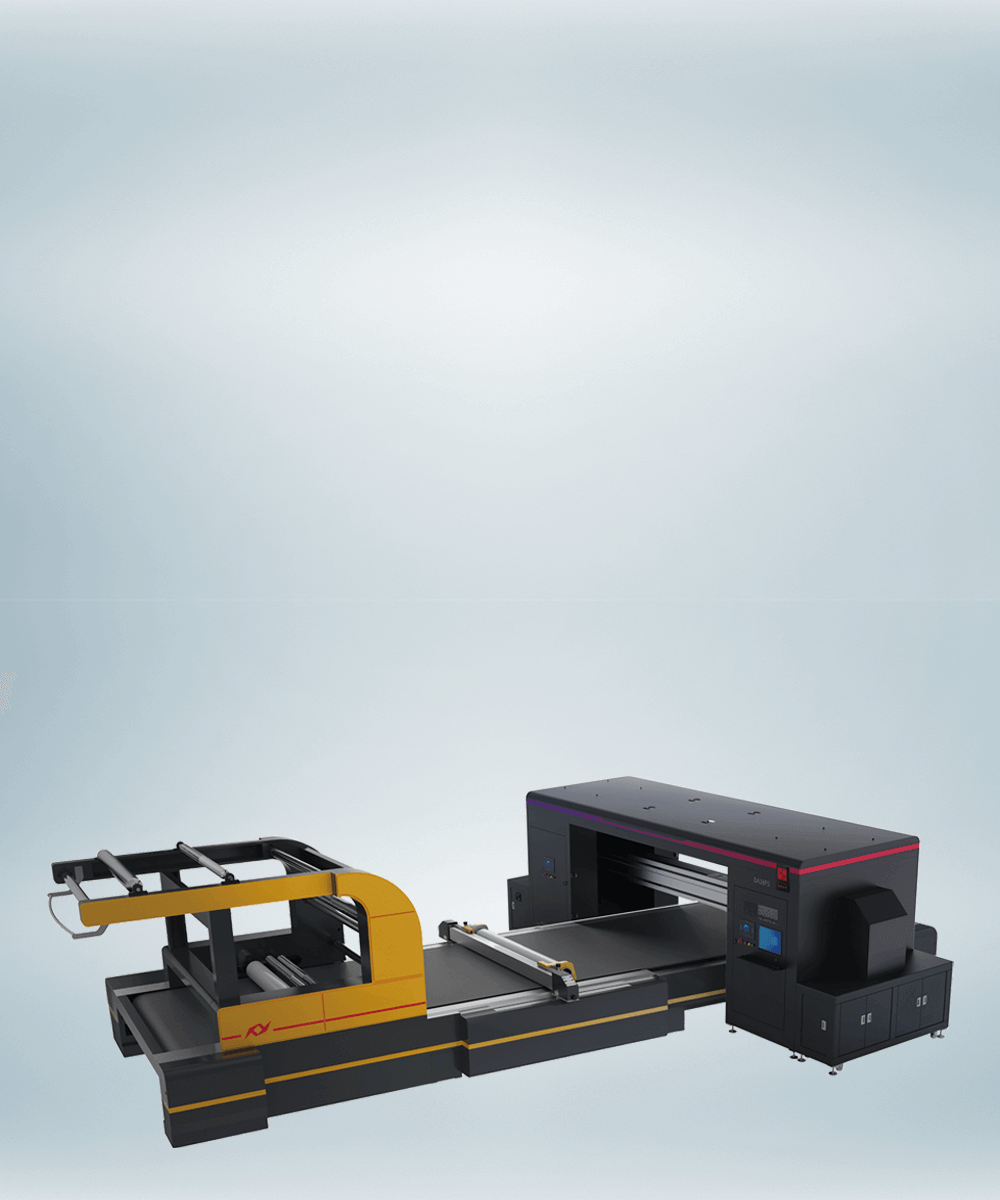

Dye Sublimation: Suitable for polyester and polymer-coated substrates, this method prints the design onto a special paper and then

transfers it to the textile using heat.

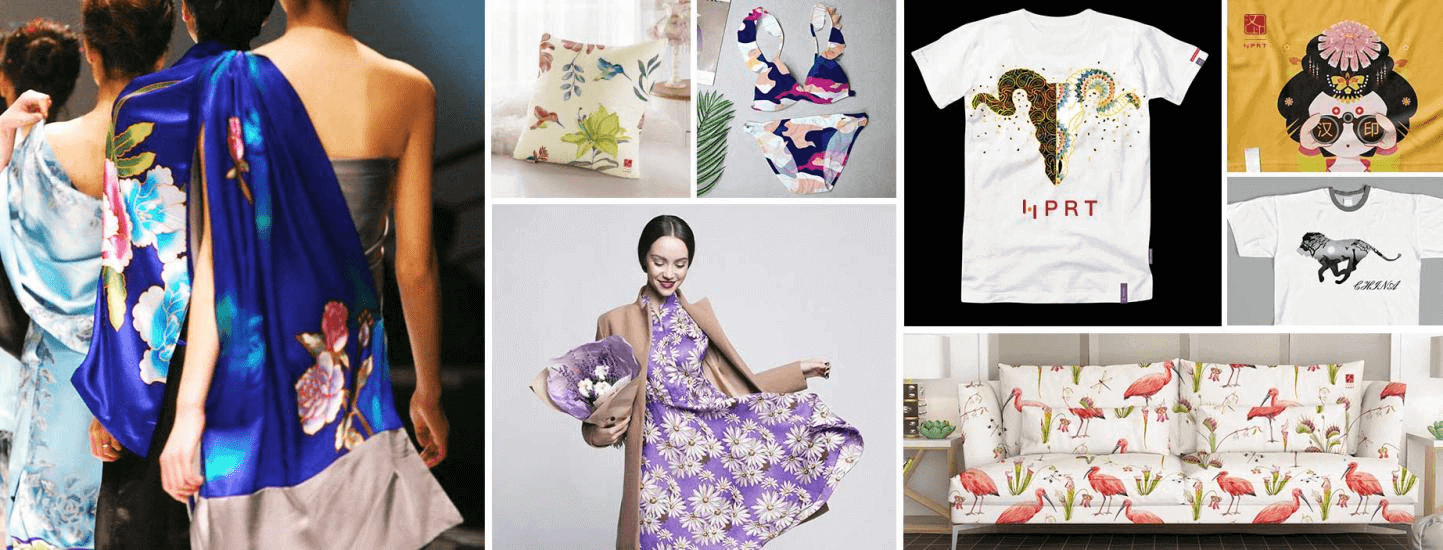

2. Select the Fabric

Different fabrics react differently to various printing methods. For instance, cotton is well-suited for DTG, while polyester works

best with dye sublimation.

3. Prepare the Design

Create or select a design, ensuring it's in the correct format and resolution for the chosen printing method.

4. Pretreat the Fabric (if necessary)

Some methods, like DTG, require pretreating the fabric to ensure ink adherence and color vibrancy.

5. Print the Design

Screen Printing: Push ink through the stencil onto the fabric in layers.

DTG: Load the fabric into the printer, and the machine prints the design directly.

Dye Sublimation: Print the design onto transfer paper, then use a heat press to transfer it onto the fabric.

6. Dry and Cure the Print

Ensure the ink is properly dried and set, which may involve heat curing or air drying, depending on the printing method.

7. Finishing Touches

This includes any additional processes like washing, steaming, or applying treatments to set the print and ensure durability.