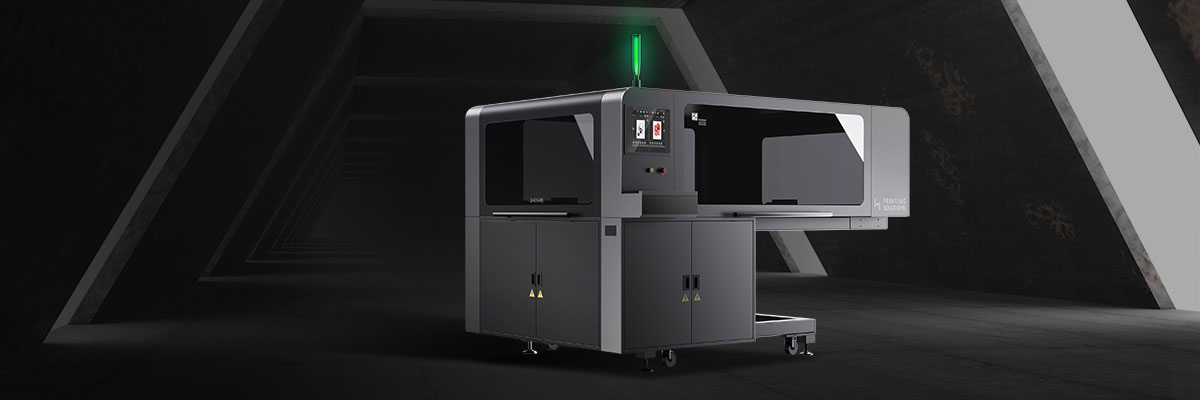

High-Volume Hybrid Digital Textile Printer - HPRT DA066M Series

Industrial print heads, print speed up to 350pcs/h

Combining technology with industry scenarios, DA066M high-volume hybrid digital textile printer integrates efficient production and high combinability into product innovation, helping to explore innovative modes of fashion design and production.

High quality presentation : Core technology for excellent quality

Upgrades in ink drop control, printing detection, ink arrangement and fabric control, etc., comprehensively improve the expressiveness of delicate pattern images, with four ink options such as acid, reactive, disperse, and pigment, making digital printing more applicable, the effect better.

High productivity: achieve efficient production

DA066M series high-volume hybrid digital textile printer combines the advantages of high productivity of oval machine and easy digital direct printing, no plate making needed with short printing cycle; makes full use of the advantages of oval machines’ multi-station to realize free combination of various processes in one machine to complete, freeing you from productivity worry.

High portfolio guarantee : More flexible operation

The flexible process and strong combination capability enables the users to freely combine screen printing with the digital printing, with the white digital printing, and the color digital printing, etc. according to the different requirements, and complete the multi-color printing at one time without affecting the productivity.

User-friendly features: Easy to maintain

The overall function is improved from the details to realize the equipment intelligence, automation and industrialization. For example, the secondary ink supply system, the intelligent drying system, the intelligent lack-of-ink alarm system, a new intelligent print head cleaning system and moisturizing device, etc., all make the equipment operation more simple and convenient.

| Model | DA066MC PRO | DA066MC EVO | DA066MW |

| Name | Hanin Hybrid DigitalTextile Printer | ||

| Printhead | Qty | Rows | Kyocera | 8 pcs | 1rows | Kyocera | 16 pcs |2rows | Dimatix | 6 pcs |2rows |

| Max. Printing width (Plate: mm) | 600*900 | 600*900(Tailor-made modelcould be700*1000) | 600*900 |

| Ink channel/ink color | 8colors | 8colors | White ink |

| Substrates applicable | Cut-piece printing: cotton, linen, silk, nylon, polyester, blended, eslatic fabric and new developed fibre | ||

| Typical printing speed (pcs/hr@A4 size) | @600*1800dpi | 3pass:300 | @600*1800dpi | 3pass:500 | @600*1800dpi|3pass:300 |

| Ink type (configured based on customer's needs) | Pigment | ||

| Ink colors (configured based on customer's needs) | C, M, Y, K, O, R, B, G, P, Lk, Lm, Lc, FM, FY | ||

| Computer system and hardware | Standard workstation computer package | ||

| RIP and software system | Hanin Task Service, Hanin RIP, NeoStampa | ||

| Machine size (L*W*H, mm) | 3330*2180*1850(printer only) | 3705*2180*1825(printer only) | 2900*2030*1825(printer only) |

| Machine weight (Kg) | 1500(printer only) | 1700(printer only) | 1500(printer only) |

| Power consumption (kW) | Printer 10kW | Printer ≤10kW | Printer ≤10kW |

| Power supply | AC380V | 3- phase 5-wire | 20A (10kW) | 50Hz/60Hz ( for the digital printer only) | ||

| Compressed air supply | 0.6MPa|1m /hr(dry, no oil or water) | ||

| Water supply | 0.4MPa|1000L/hr | ||

| Operating temperature | 20~30 | ||

| Operating humidity | 45%-75%(no condensing) | ||