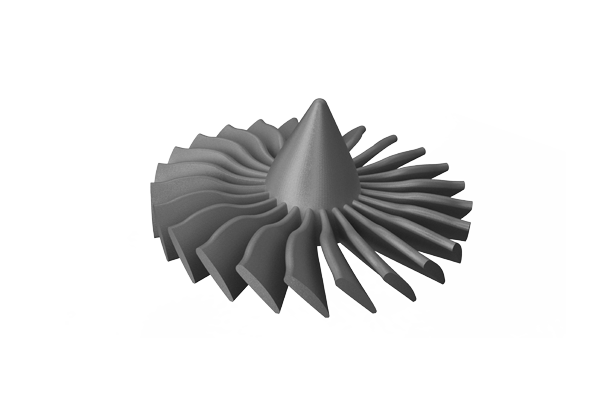

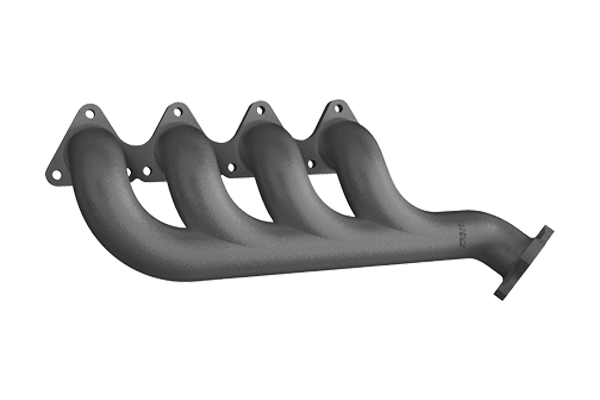

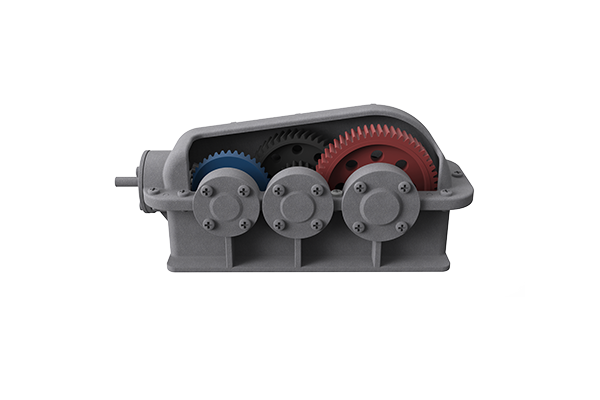

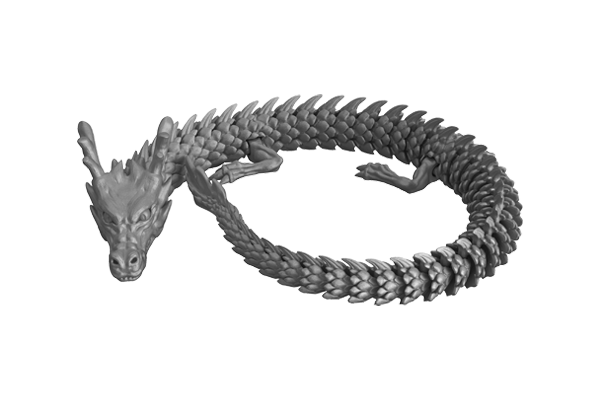

HPRT's additive manufacturing (3D printing) technology encompasses Selective Jet Fusion (SJF), Selective Laser Melting (SLM), Stereolithography (SLA), Selective Area Light Transmission (LCD), Digital Light Processing (DLP), and Fused Deposition Modeling (FDM). These technologies enable printing with various materials such as nylon, plastic, and metal, catering to the diverse needs of industries including industrial manufacturing, healthcare, automotive, aerospace, and consumer goods. Additionally, HPRT offers comprehensive 3D printing post-processing solutions, including dyeing treatment and powder cleaning processing equipment.

Material: Nylon. Characteristics: High strength, good toughness, and heat resistance up to 120°C

Post-processing options: Polishing, coloring, UV treatment, and more

Characteristics: High printing precision, high resolution, and smooth surface finish

Characteristics: Low density, high strength, good corrosion resistance, and excellent castability

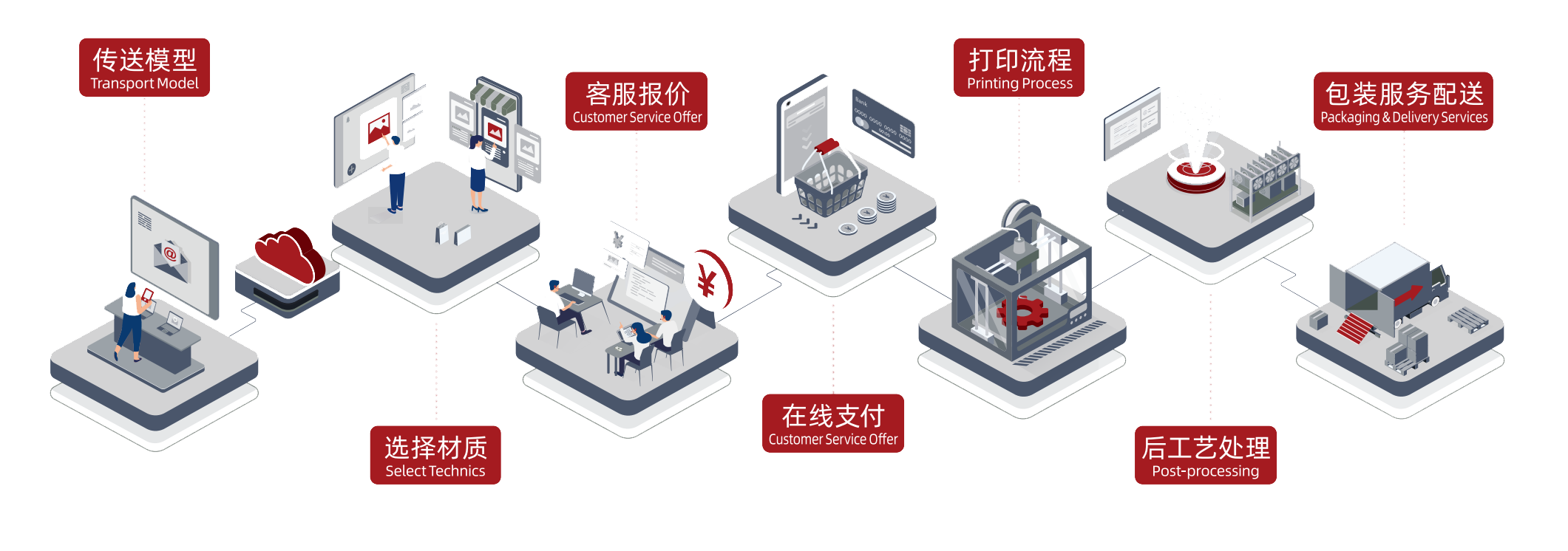

As a leading professional 3D printer developer and manufacturer in China, HPRT not only provides equipment but also offers comprehensive 3D printing services. Our company has independently developed a range of high-end 3D printing equipment, positioning us at the forefront of the industry in both technology and scale. We are committed to delivering high-quality, efficient 3D printing services for prototype models.

HPRT's 3D printing technology is widely applied across various sectors of the manufacturing industry. Particularly during the product development stage, 3D printed prototypes can significantly reduce the risks associated with direct mold opening and allow for effective validation before mass production. This service is ideal for key preliminary activities such as exhibitions, appearance and functionality verification, and market promotion. Additionally, HPRT offers personalized customization and small-batch production services to meet the diverse needs of our customers.

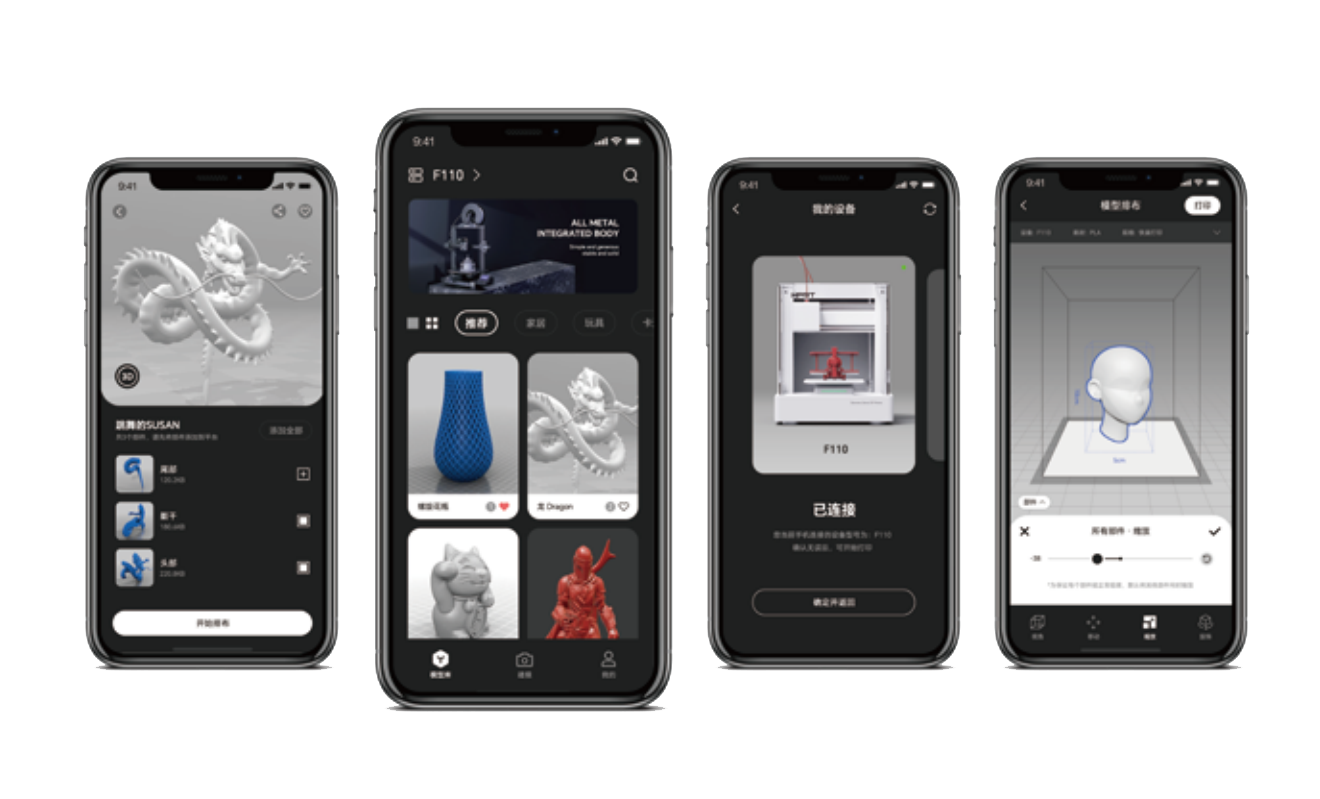

Hanin 3D is a convenient and user-friendly 3D printing software that features a rich model library and cloud slicing, supporting remote printing and photo printing. It allows everyone to create and print 3D objects, enjoying the fun and charm of intelligent 3D printing.

Suitable for F110,F210and other consumer-grade 3D printers

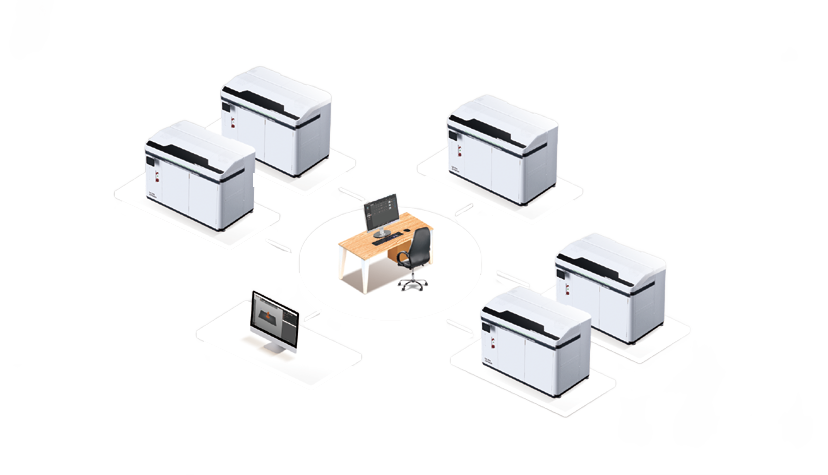

The SJF-P380 system is an integrated hardware and software solution tailored for Hanin's industrial 3D printing technology. This system integrates multiple efficient software applications, supporting the monitoring and optimization of the entire process from design to production. It helps customers improve production efficiency, reduce production costs, and ensure the excellence of product quality.

Suitable for SJF-P380 and other industrial-grade 3D printers

● Printer System

● Processing Station System

● Slicing and Packaging Tools

● Printing Management Tool

The Hanin Industrial IoT Platform is applied in the field of industrial manufacturing, utilizing internet and IoT technologies to achieve automation, intelligence, and networking in enterprise manufacturing. The platform connects 3D printers and associated devices, enabling data collection, transmission, processing, storage, and analysis. It also supports remote control and monitoring of equipment, providing comprehensive services and support for enterprise production and manufacturing.

upports equipment remote systemupdate to reduce operation

supports the acquisition of avariety of sensor data

supports data visualization, such as data anomaly detection

supports enterprise-level privatedeployment system

Provides device registration, authentication, supports unified management of multiple devices

adopts advanced encryption technology to protect data security

supports setting strict accesscontrol policies

pushes the alarm information in time when the equipment is faulty or abnormal

Xiamen Hanin Co., Ltd. is a national high-tech enterprise specializing in the research and development, production, sales, and service of printing equipment, dedicated to becoming a global leader in the printing industry. With its independently developed core precision technology, it has won honors such as "National Specialized, Refined, and New 'Little Giant' Enterprise," "National Service-oriented Manufacturing Demonstration Enterprise," and "National Manufacturing Single Champion Demonstration Enterprise," as well as important awards like the "German Red Dot Best Design Award" and the "China Patent Award." Additionally, it has established industry-academia research institutes with several scientific research institutions, becoming an industry pioneer.

Hanin Additive Manufacturing Division integrates the research and development, production, and sales of 3D printers and consumables, flexible printing services, and industrial printing software support to provide comprehensive additive manufacturing solutions. Focusing on technologies such as powder bed fusion, laser sintering, and photopolymerization, the product line includes consumer-grade and industrial-grade 3D printers, supporting consumables, software, and solutions. Adhering to a "multi-technology, collaborative development" approach, it actively promotes the application of additive manufacturing technologies in aerospace, automotive, medical, mold, and education fields, meeting the diverse needs of different customers, helping enterprises reduce costs and increase efficiency, and enabling personalized customization. While emphasizing technology research and product innovation, the division is also committed to promoting the construction and application of the industrial ecosystem, empowering customers, and assisting in the transformation and upgrading of the manufacturing industry.

The application industries include aerospace and automotive manufacturing, consumer 3C products, dentistry, medical, education, industrial applications, art design, toys, and figurines.