HPRT TTO(Thermal Transfer Overprinting) printers provide an ideal solution for precise coding and marking on flexible packaging, films, and labels. Designed for real-time and variable data printing, they efficiently handle expiry dates, 1D and 2D barcodes, batch numbers, logos, ingredient lists, and pricing. These thermal transfer overprinters seamlessly integrate into both horizontal and vertical packaging machines and production lines, making them a valuable asset in industries such as pharmaceuticals, food, and logistics.

Features an 8-inch color touchscreen for straightforward operation, with an icon menu and shortcut keys for easy navigation. The user-friendly interface ensures accuracy, while detailed diagnostics and password protection enhance reliability. Supports convenient on-site template editing.

Offers simple installation and versatility, easily mountable on various packaging machines and compatible with other TTO products, reducing additional costs.

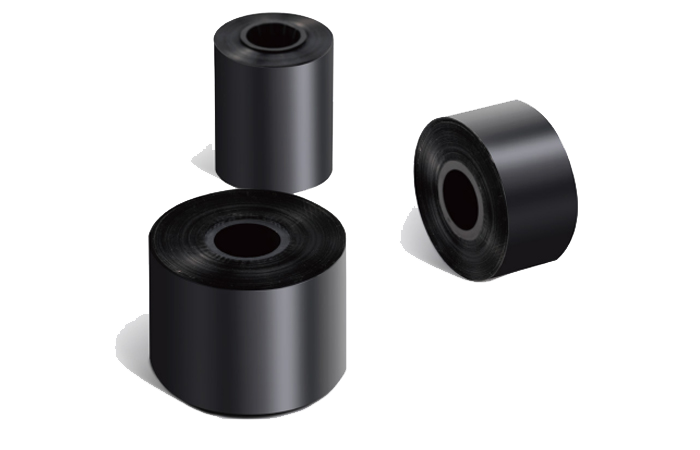

Rich colors and various sizes thermal transfer overprinting ribbons. HPRT FC/EFC Series ribbon cassette is design for easy installation and fast ribbon replacement. Accommodates up to 900mm ribbon length, compatible with all machine models, reducing spare part costs.

● Reliability: Automatic ribbon tension control, minimal 0.5mm gap between prints, reducing downtime and print errors.

● Ease of Use: Simple setup and maintenance with no special training required for the Android controller.

● Efficiency: The ribbon can move in two directions while maintaining the appropriate tension - ensuring only a 0.5mm gap between two prints. When the ribbon is not used, it can be reused after each print to achieve optimal efficiency

● Flexibility: Compatible controller for models FC53, FC32.

A coding machine(printer), is a device used for imprinting information like dates, batch numbers, MRP, or product details on packaging materials. There are two primary coding methods in the market:

Inkjet Coding Machines: Use ink to print codes without touching the product.

Laser Coding Machines: Employ lasers to etch codes onto surfaces.

Ink Roll Coder: Applies ink directly onto the product through physical contact.

Hot Stamp Coding: Uses heat and pressure to transfer coding from a foil to the product.

Thermal Transfer Overprinting (TTO): Transfers ink from a ribbon to the product using heat.

Heat Sealing Coding Machine: Imprints codes during the heat sealing process of packaging.

TTO is short for thermal transfer overprinting. TTO Printing is a printing process requires a thermal transfer printhead(TPH) of the TTO printer and ribbon to contact the packaging material.

Step 1. The tiny heating point of TPH enables printing to reach a printing resolution of 300 dpi (12 dots/mm).

Step 2. The ink on the ribbon is melted by instant heating and then transferred to the packaging material.

Step 3. Printing can be formed on the packaging material through the relative movement of the TPH and the ribbon and the packaging material.

Step 4. Intelligent control enables the heating point to print various contents on the packaging materials.

Print Pricing, Dates, Times, Trace ability info, Barcodes, Logos, Ingredient statements, Promotional Messaging on consumer packaged goods and pharmaceutical soft packaging.

Packaging Machine Type: Determine if it's vertical or horizontal, intermittent or continuous.

Packaging Film Type: Assess compatibility with materials like polypropylene, polythene, paper, metalized foil, or a mix.

Film Speed: Evaluate if the film speed fluctuates, increasing or decreasing during operation.

Print Frequency: Consider the number of products printed per minute.

Image Specifications: Look at the size and orientation of the image, along with variable information needs.

Mounting: Check if the TTO printer supplier offers bracket that fits your setup.

Sample Production: Confirm if samples have been produced at the required speed and quality.

Ribbon Suitability: Determine whether the standard ribbon is adequate or if a resin ribbon is needed.

Suitability for Environment/Application: Assess if the environmental conditions and application are appropriate for thermal transfer technology.