A. Natural Fibers: The Absorbent Canvas

Natural fibers are derived from plants and animals. They are known for their breathability, comfort, and luxurious feel.

Examples: Cotton, Linen, Silk, Wool, Viscose.

The Core Challenge: High Absorbency.

Think of a cotton fiber like a tiny sponge. When you apply a liquid ink droplet, it naturally wants to spread and bleed, which can result in fuzzy edges and less vibrant colors.

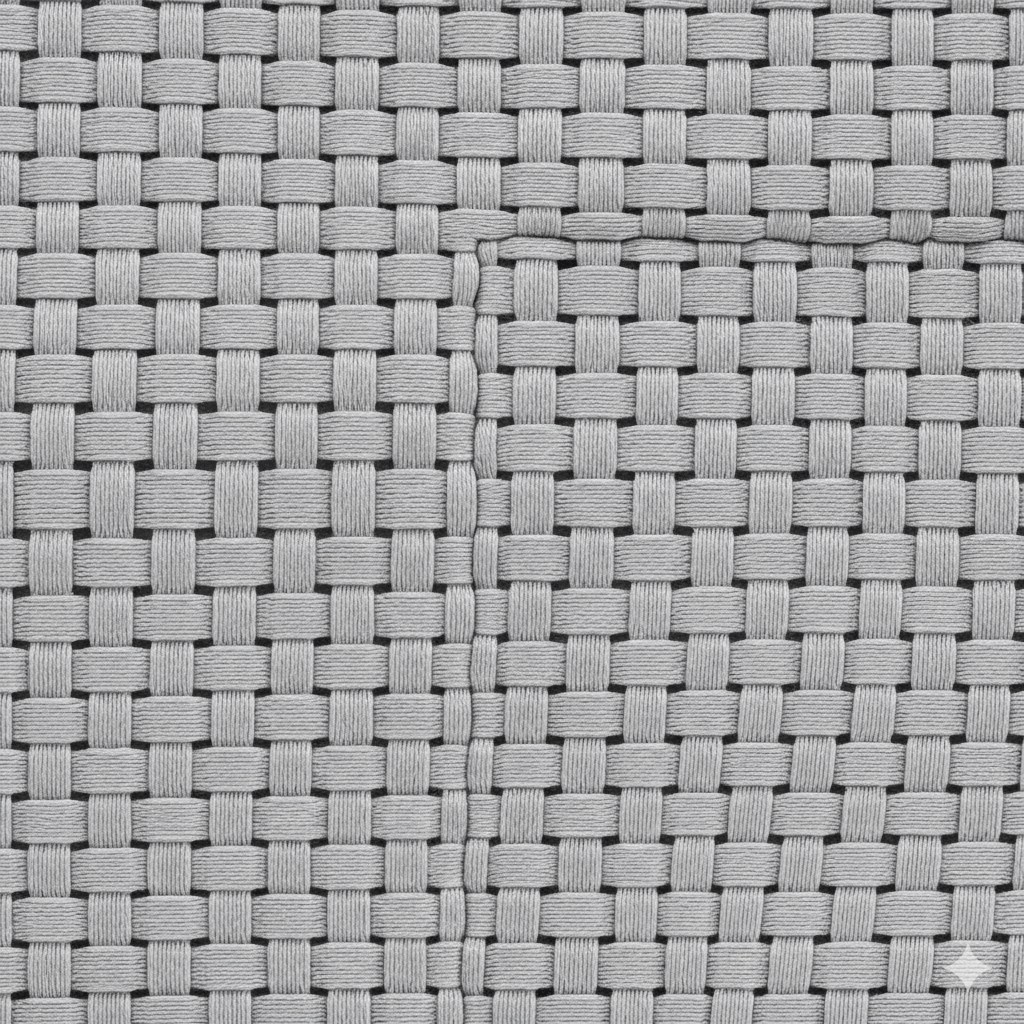

The Solution: Pre-treatment.

To achieve sharp, brilliant prints on natural fibers, a pre-treatment process is essential. A specialized liquid coating is applied to the fabric before printing. This coating acts as a primer, controlling the ink spread and ensuring the dye bonds chemically and permanently to the fibers.

Required Inks: This chemical bonding is achieved with Reactive inks (for cotton, linen, viscose) or Acid inks (for silk, wool, nylon). Pigment inks, which sit on the surface, are also a versatile option for most natural fibers.