Businesses usually go for thermal transfer printers to print barcode labels that stay clear and last long. Today, thermal transfer printing is widely used in manufacturing plants, logistics hubs, healthcare labs, and retail warehouses.

In this guide, we’ll explore what thermal transfer printing is, how it works, its main types and benefits, and how to choose the right printer for your business.

What Is a Thermal Transfer Printer?

A thermal transfer printer is a device that uses heat to transfer ink from a ribbon onto a printing medium such as paper, polyester (PET), or polypropylene (PP). It’s also commonly referred to as a thermal ribbon printer.

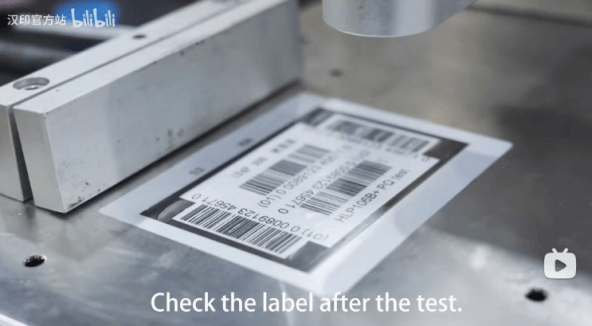

The process produces crisp, high-resolution images, barcodes and texts that resist fading, abrasion, and heat.

How Does Thermal Transfer Printing Work?

The printing process involves three main components:

- ● Printhead: Applies precise heat to the ribbon.

- ● Ribbon: A thin film coated with solid ink (wax, wax-resin, or resin).

- ● Substrate: The printing surface — typically a label or tag material.

When the printhead heats specific dots on the ribbon, the ink melts and bonds permanently to the label surface. The result? Sharp, durable prints that maintain quality even in harsh environments — such as asset silver labels, electronic product SN barcode labels, and large chemical-resistant drum labels on industrial containers.

The advantages of thermal transfer printing are clear:

High precision: Produces sharp barcodes and small text, up to 300 dpi or higher.

Material flexibility: Works on paper, PET, and synthetic labels.

Durable and professional results: Resistant to heat, moisture, and chemicals, delivering a smudge-free, long-lasting finish — especially on PET and PP labels.

Reliable for industry use: Ideal for logistics, electronics, and chemical labeling.

Thermal Transfer vs Direct Thermal Printing

Thermal printing can be divided into direct thermal and thermal transfer printing. Both methods use heat, but their durability and applications differ significantly.

Direct Thermal Printing

Direct thermal printing is a method that creates images by applying heat directly to specially coated, heat-sensitive paper. It doesn’t use ink, toner, or ribbons — the printhead selectively heats areas of the paper to form text or barcodes. This process is simple and cost-efficient but the prints tend to fade over time when exposed to heat, light, or friction.

Thermal Transfer Printing

Thermal transfer printing, on the other hand, uses a ribbon to create durable, high-quality prints on various materials. It’s ideal for applications that require long-lasting or outdoor labels.

So, the key difference between them lies in print durability, material compatibility, and application lifespan — direct thermal for short-term use, and thermal transfer for long-term labeling.

The table below summarizes how thermal transfer printing differs from direct thermal printing.

| Feature | Thermal Transfer Printing | Direct Thermal Printing |

|---|---|---|

| Ink Source | Uses ribbon (wax/wax-resin/resin) | No ribbon (heat-sensitive paper) |

| Durability | Long-lasting, resistant to heat and light | Fades over time |

| Cost | Slightly higher (ribbon required) | Lower consumable cost |

| Applications | Asset tags, barcode labels, outdoor labeling | Shipping labels, receipts |

| Material Variety | Paper, PET, PP, Nylon, etc. | Thermal paper only |

Types of Thermal Transfer Printers

Thermal transfer printers are key tools for printing sharp, durable barcodes and labels — especially for monochrome printing. They usually fall into three main types, based on their design and how they’re used.

Desktop Thermal Transfer Printers

Small-footprint and reliable, desktop thermal transfer printers are ideal for low to medium print volumes, typically ranging from a few hundred to a few thousand labels per day.

- ✔️ Features: Compact design, easy operation, and economical maintenance.

- ✔️ Print width: 2-inch to 4-inch (203/300 dpi).

- ✔️ Applications: Suitable for printing product labels, shelf tags, and small-batch barcodes — ideal for offices, retail stores, laboratories, and small businesses.

Looking for an affordable solution?

Check out our cheap thermal transfer printers for small business

Industrial Thermal Transfer Printers

Factories and production lines often use industrial thermal transfer printers for large-volume, continuous label printing in demanding environments. These industrial thermal printers deliver stable, high-speed performance and can handle thousands of labels per day.

- ✔️ Features: Rugged metal housing, large ribbon capacity, and high-speed printing (up to 14 ips).

- ✔️ Print width: 4-inch to 8-inch (203/300/600 dpi).

- ✔️ Applications: Commonly used for printing shipping labels, pallet tags, compliance labels, and asset tracking tags in manufacturing, logistics, and warehousing.

Need a printer built for demanding environments?

Explore our industrial thermal transfer printers for barcodes

Mobile Thermal Transfer Printers

Need to print durable labels on the go — such as asset tags or cable labels? Then mobile thermal transfer printers are the perfect choice. These printers are lightweight and battery-powered, allowing operators to easily create labels anytime, anywhere — in warehouses, offices, or field service sites — improving both efficiency and accuracy.

- ✔️ Features: Lightweight design, wireless connectivity (Bluetooth/Wi-Fi), and long-lasting battery life.

- ✔️ Print width: 2-inch to 3-inch.

- ✔️ Applications: Ideal for cable labeling, asset management, inventory control, and field service tasks.

Types of Thermal Transfer Ribbons and Compatible Labels

The ribbon is one of the most important consumables used in thermal transfer printers. The ribbon you choose directly impacts print quality and durability. There are three thermal transfer ribbon types:

| Ribbon Type | Composition | Key Features | Best Used On |

|---|---|---|---|

| Wax Ribbon | Wax-based ink | Economical, suitable for standard paper labels | Shipping labels, retail tags |

| Wax-Resin Ribbon | Blend of wax and resin | Scratch-resistant, sharper print quality | Coated paper, synthetic labels |

| Resin Ribbon | Pure resin formulation | Ultra-durable, chemical & heat resistant | Polyester (PET), nylon, PVC labels |

As shown above, each ribbon type has distinct features and compatible label materials. Users should take note of these details when choosing the right ribbon for their printer.

To learn more about ribbon structure and applications, check out How to Choose the Right Thermal Transfer Ribbons

How to Choose the Right Thermal Transfer Printer

Choosing the right thermal transfer printer depends on how and where you plan to use it. A few key factors can help you make the best decision for your labeling workflow:

-

●

Print Volume Industrial models for high-volume operations, desktop for moderate use. Depending on your workload, you can go for a high-speed printer for continuous printing or a standard-speed model that balances speed and cost.

-

●

Label Size Choose a printer that fits your label size. A 4-inch thermal transfer printer works for most businesses, while 6- or 8-inch thermal printers are better for larger industrial or logistics labels.

-

●

Print Quality Check what your labels face — like humidity, heat, chemicals, or scratches. Then pick the right material and ribbon, and make sure your printer can handle them.

-

●

Print Resolution 203 dpi for standard barcodes, 300+ dpi for graphics or small fonts.

-

●

Connectivity USB, Ethernet, or Wi-Fi, depending on your workflow.

-

●

Printer Expandability Some labeling jobs need more than basic printing. For example, clothing tag printer may require a rotary cutter for precise trimming wash labels, while industrial models can include a peeler module for faster workflows.

Hanin(HPRT): Professional Solutions for Durable Label Printing

Hanin offers a complete range of thermal transfer label printers trusted in retail, food, healthcare, and industrial manufacturing. They help small businesses, warehouses, and factories print with precision and efficiency — every day.

Hanin thermal transfer printers feature:

- ● Durable construction built for continuous and industrial use.

- ● Sharp, consistent printing for barcodes, text, and graphics on a wide range of materials.

- ● Compatibility with multiple ribbon types (wax, wax-resin, resin).

- ● Easy integration with warehouse management and ERP systems.

- ● Comes with label software and options like peel-off, or rotary cutter modules.

- ● Long service life with low maintenance costs.

Whether labeling medical samples or industrial components, Hanin delivers dependable performance and lasting print quality.

Thermal transfer printing continues to be the most reliable method for durable barcode label production. By understanding how it works, its advantages, and its types, you can choose the best solution for your business.

Find the Right Label Printer for Your Business.

Power your operations with HPRT — trusted worldwide for durable, high-performance professional label printers.

Thermal Transfer Printing FAQs

Q1 What is the difference between thermal and direct thermal printing?

Thermal transfer uses a ribbon to produce permanent, durable labels, while direct thermal printing burns images directly onto heat-sensitive paper — ideal for short-term labels.

Q2 Which ribbon should I use for thermal transfer printing?

Choose based on your material: wax for paper, wax-resin for coated surfaces, and resin for synthetic or industrial labels.

Q3 What industries use thermal transfer printers?

Logistics, manufacturing, healthcare, retail, and packaging — anywhere that long-term label readability is critical.