1. Continuous Mode

What It Is:

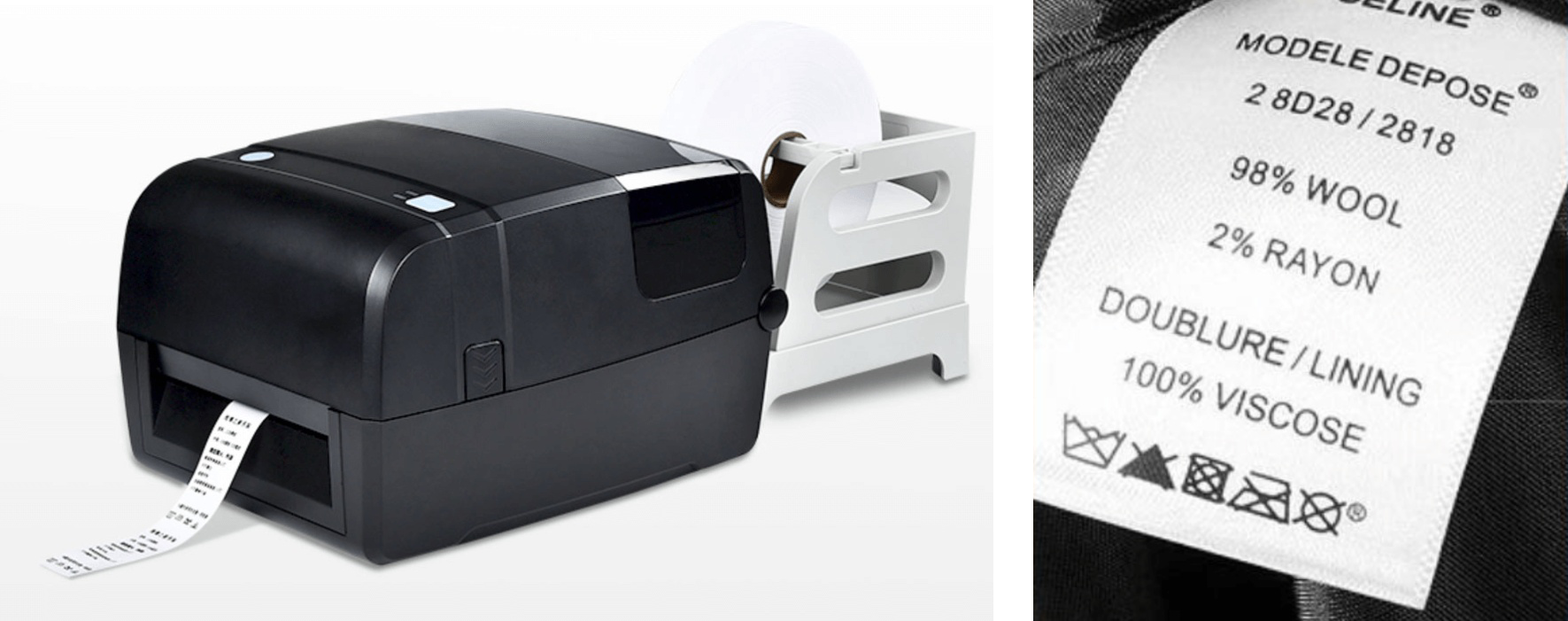

Continuous mode allows the thermal printer to print on an unbroken roll of labels or media without predefined gaps. Labels come out in a continuous stream, and it's up to the user to cut or tear them manually.

This mode requires high precision in paper feeding and motor control, as there are no sensor-based cues to identify the start and end of a label.

In continuous label printers, accurate stepping algorithms are essential to maintain consistent print lengths and prevent misalignment or image shifting during high-speed output.

When to Use It:

Ideal for printing long labels, tickets, or custom-sized outputs where precise cut points are not predefined. It's also used when labels are printed in bulk and separated later.

Pros:

- ✓ Fast printing with no pauses between labels

- ✓ Great for custom-sized or long-format labels

Cons:

- ✗ Requires manual cutting or tearing

- ✗ Not suitable for pre-cut or individual labels