Thermal Paper vs. Regular Paper:

What's the Difference and How to Choose

If you’ve ever waited at a checkout, peeled a shipping label, or printed a ticket, you’ve handled thermal paper — that smooth, shiny roll that creates a crisp black print without a single drop of ink. But back in the office, we rely on regular paper for contracts and flyers.

They look similar at a glance, but under the hood, they are opposites.

Most guides just tell you one needs ink and the other doesn't. But if you are running a business, you need to dig deeper. In this guide, we’ll look at the actual science, break down the "hidden costs" that make one much cheaper than the other, and explain why choosing the right paper is actually about choosing the right workflow.

How Does Thermal Paper Work? (The Science)

Thermal paper isn't just paper; it’s a piece of technology. Unlike regular paper, which is just wood pulp waiting for ink, thermal paper is a multi-layered system designed to react to heat.

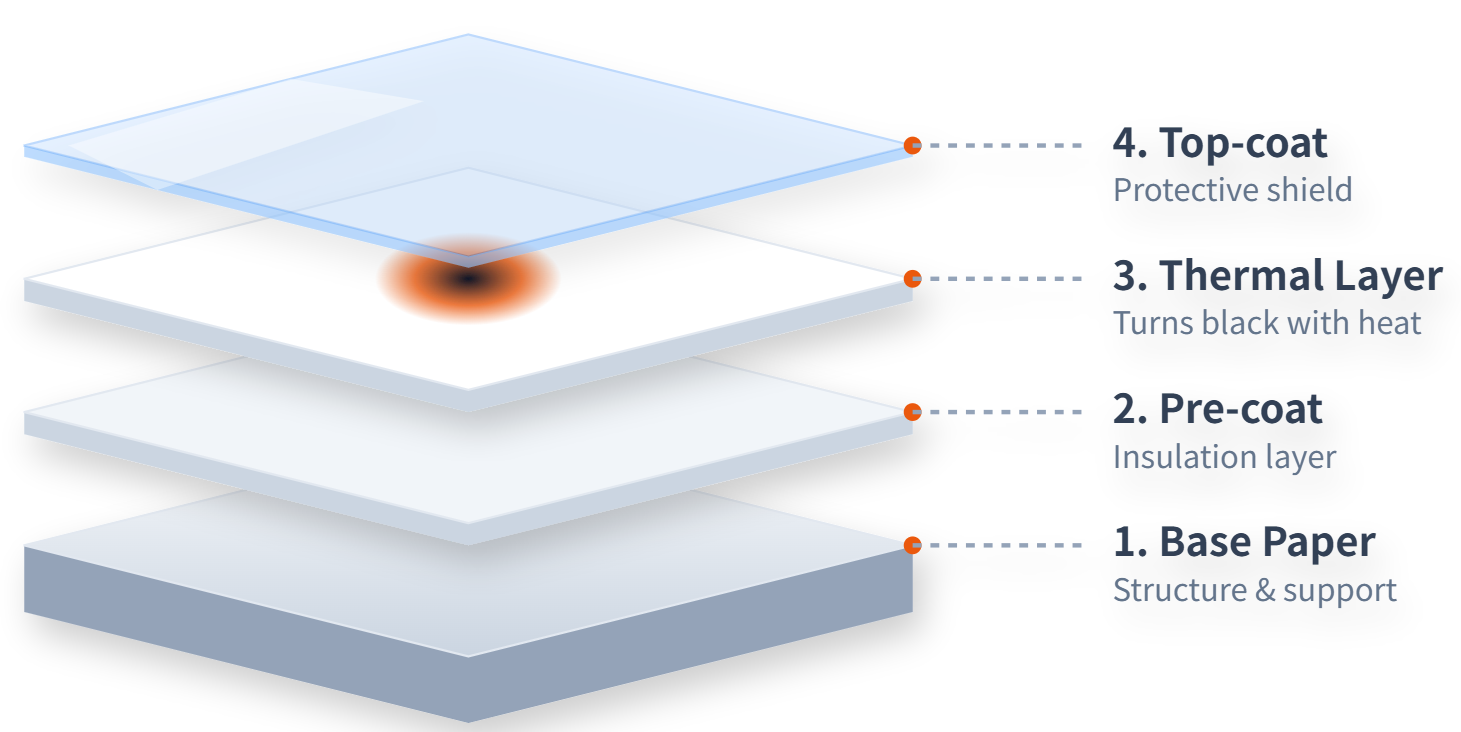

To understand why it behaves the way it does, you have to look at its anatomy:

-

1

Base Paper: The foundation layer that provides structure.

-

2

Pre-coat (Undercoating): Think of this as a primer. It smooths the surface and acts as insulation, ensuring the heat stays focused on the chemical layer for a sharper print.

-

3

Thermal Layer: This is where the magic happens. It holds a leuco dye and a developer. When the thermal printer head warms up specific dots, these chemicals melt and react, turning black instantly.

-

4

Top-coat (Premium Only): High-quality thermal papers (like labels) add a protective top layer. This acts like a shield against water, oil, and scratches, preventing the print from fading too soon.

The Result: You get an instant print with zero ink, toner, or ribbons.

What is Regular Paper?

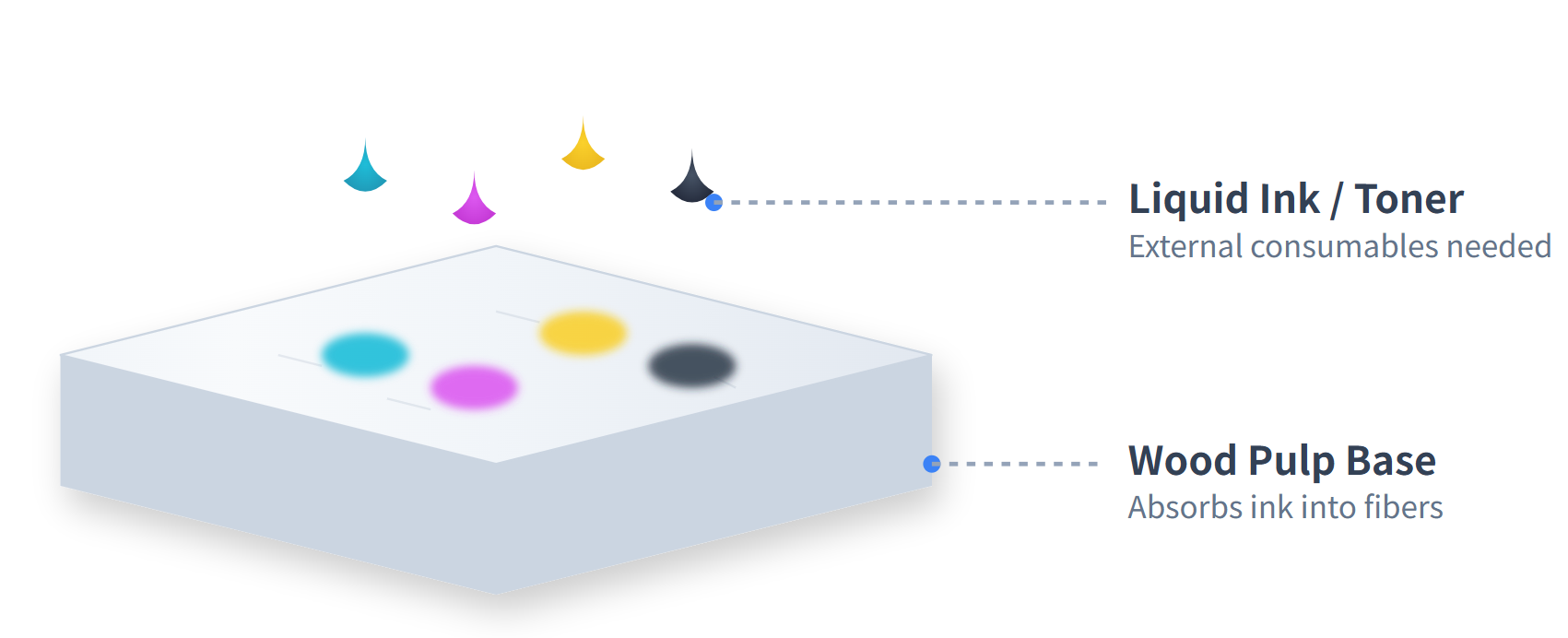

Regular paper (bond, copy, or offset paper) is passive. It has no chemical coating. It relies on absorption:

Inkjet Printers

Spray liquid ink that soaks into the paper fibers.

Laser Printers

Use heat to fuse plastic toner powder onto the surface.

Thermal vs. Regular: The Real Differences

While regular paper is the standard for documents, thermal paper dominates logistics and retail. Here is the breakdown.

| Feature | Thermal Paper (Direct) | Regular Paper (Plain) |

|---|---|---|

| Ink / Toner Needed | ✘ No (Paper is ink) | ✔ Yes |

| Print Speed | Very Fast | Moderate |

| Durability Type | Survival: Resists water/oil | Archival: Lasts 50+ years |

| Image Precision | High (Perfect edges) | Medium (Ink bleeds) |

| Recyclability | ✘ No | ✔ Yes |

Deep Dive 1: Durability vs. Survivability

It’s a common mistake to think regular paper is "more durable." We need to distinguish between lasting a long time and surviving harsh conditions.

- Regular Paper is the "Archival Master": If you file a contract in a dark cabinet, it will last for decades. But if a drop of rain hits an inkjet shipping label? The ink runs, and the address becomes unreadable.

- Thermal Paper is the "Survival Expert": While thermal prints may fade over time, they are built for the rough journey of shipping. Top-coated thermal labels are water-proof, oil-proof, and scratch-resistant. They survive rain, grease, and friction.

Deep Dive 2: Why Thermal Wins for Barcodes

Why do scanners prefer thermal prints? It comes down to the edges.

- Regular Paper: Liquid ink naturally bleeds slightly into paper fibers. To a scanner, these fuzzy edges create errors.

- Thermal Paper: The heated printhead creates precise, square pixels on the coating without bleeding. This creates the razor-sharp contrast that ensures your package gets scanned correctly every time.

The True Cost: Why "Cheap" Paper is Expensive

A ream of regular copy paper costs less than a roll of thermal labels. But this is a "false economy." You have to look at the Total Cost of Ownership (TCO).

The Ink Factor

Ink is expensive. Printing solid black barcodes and text on regular paper burns through cartridges fast.

The Waste Factor

With regular A4 paper, you often print one small label and throw away the rest of the sheet. Thermal printers dispense the exact size needed—zero waste.

The Maintenance Factor

Regular printers have moving parts and ink nozzles that clog. Thermal printers are mechanically simple and rarely break down.

Verdict: For high-volume printing (like shipping labels), thermal printing is significantly cheaper per print because you eliminate the recurring cost of ink.

DIY Test: How to Identify Thermal Paper in 1 Second

Not sure what kind of paper you are holding? Try these simple tests:

The Scratch Test (Easiest)

Just scratch the paper quickly with your fingernail. If a dark grey mark appears, it is thermal paper. The friction from your nail created enough heat to activate the chemicals.

The Sheen Test

Thermal paper usually has a smoother, slightly waxy surface compared to the matte texture of regular bond paper.

The Heat Test

Hold the paper near a warm lightbulb or mug. Thermal paper will darken; regular paper won't change.

Can You Swap Them? (Hardware Constraints)

We often get asked if you can use the "wrong" paper in a printer. The short answer is no.

Can I use regular paper in a thermal printer?

No. The printer applies heat, but since regular paper lacks the chemical coating, it will come out completely blank.

Can I use thermal paper in an inkjet/laser printer?

No, and it’s risky.

- Inkjet: The ink won't dry on the slick thermal coating, making a mess.

- Laser: The extreme heat of the fuser will turn the entire thermal sheet black instantly and could melt the coating onto your printer's rollers, ruining the machine.

Which Printing Ecosystem Should You Choose?

Since you can't swap the paper, you are really choosing a Printing Ecosystem. Use this matrix to decide which setup fits your business needs.

The Thermal Ecosystem

Best For: Efficiency, Speed, and Low Maintenance.

Ideal Scenarios: Shipping labels (50+ a day), POS receipts, barcodes, temporary warehouse tags.

"You need a workhorse that prints instantly without stopping for ink changes."

The Traditional Ecosystem

Best For: Versatility, Color, and Archiving.

Ideal Scenarios: Contracts, legal documents, marketing flyers, color photos.

"You need the document to look professional in a meeting or last for 20 years in a file cabinet."

Summary: Matching the Job to the Paper

| If your goal is... | You need this Printer | And this Paper |

|---|---|---|

| Shipping Labels / Barcodes | Direct Thermal Printer | Thermal Label/Sticker Paper |

| Business Contracts | Laser Printer | Standard Copy Paper |

| Retail Receipts | Thermal Receipt Printer | Thermal Roll Paper |

| Color Photographs | Inkjet Printer | Photo Paper (Regular) |

| Scrapbooking / Stickers | Mini Thermal Printer | Thermal Sticker Paper |

Health & Environmental Considerations

- BPA/BPS Safety: Historically, thermal coatings used BPA. Today, reputable brands like offer BPA-Free and Phenol-Free thermal papers. It's always worth checking the label to be safe.

- Recycling: This is a crucial distinction. Regular paper is recyclable. However, due to the chemical coating, thermal paper is generally NOT recyclable and should go in the trash to avoid contaminating recycled pulp.

Conclusion

Thermal paper and regular paper aren't really competitors; they are specialists.

Regular paper is the master of the office—perfect for letters, contracts, and color. But for the fast-paced world of logistics and retail, thermal paper is the undisputed choice. Its ability to produce ink-free, water-resistant, and machine-readable prints instantly makes it the smartest option for shipping labels and receipts.

By understanding the science and cost logic, you can stop wasting money on ink and pick the right tool for the job.