Printers have come a long way. Modern printer types now go far beyond basic documents—they handle crisp photos, barcode labels, and even 3D models. With so many different types of printers available, it’s easy to feel overwhelmed. Should you choose inkjet, laser, thermal, or something else?

This article will look at the the main printer types, weigh their pros and cons, and help you decide which kind of printer works best for your needs.

Main Types of Printers at a Glance

There are various types of printers on the market today, and they can generally be categorized by their printing technology into:

Each printer type has unique strengths and limitations. Some focus on speed, others on image quality, while many balance cost and versatility. Up next, we’ll break down the different categories of printers and show you where each one really shines.

8 Printer Types with Pros, Cons, and Best Uses

Inkjet Printers

Inkjet printing took off in the late 1970s and early 1980s, when companies like HP, Canon, and Epson brought the technology to consumer markets. The idea was simple yet powerful — use tiny nozzles to spray ink directly onto paper, creating sharp text and vivid images without the clunky mechanisms of older impact printers.

How Inkjet Printer Works:

An inkjet printer pushes liquid ink through microscopic nozzles, firing controlled droplets onto the paper. The placement is so precise that it can form smooth gradients and detailed graphics. Some models use heat to form bubbles (thermal inkjet), while others rely on piezoelectric elements for precise droplet control.

Inkjet Printer Types and Uses:

Home Use

- ●Home Inkjet Printers: Suitable for printing family photos, schoolwork, and small batches of documents.

Business Use

- ●Office Inkjet Printers: For color documents, reports, and brochures.

- ●Wide-Format Inkjet Printers/Plotters: For advertising prints, CAD drawings, and engineering plans.

Industrial Use

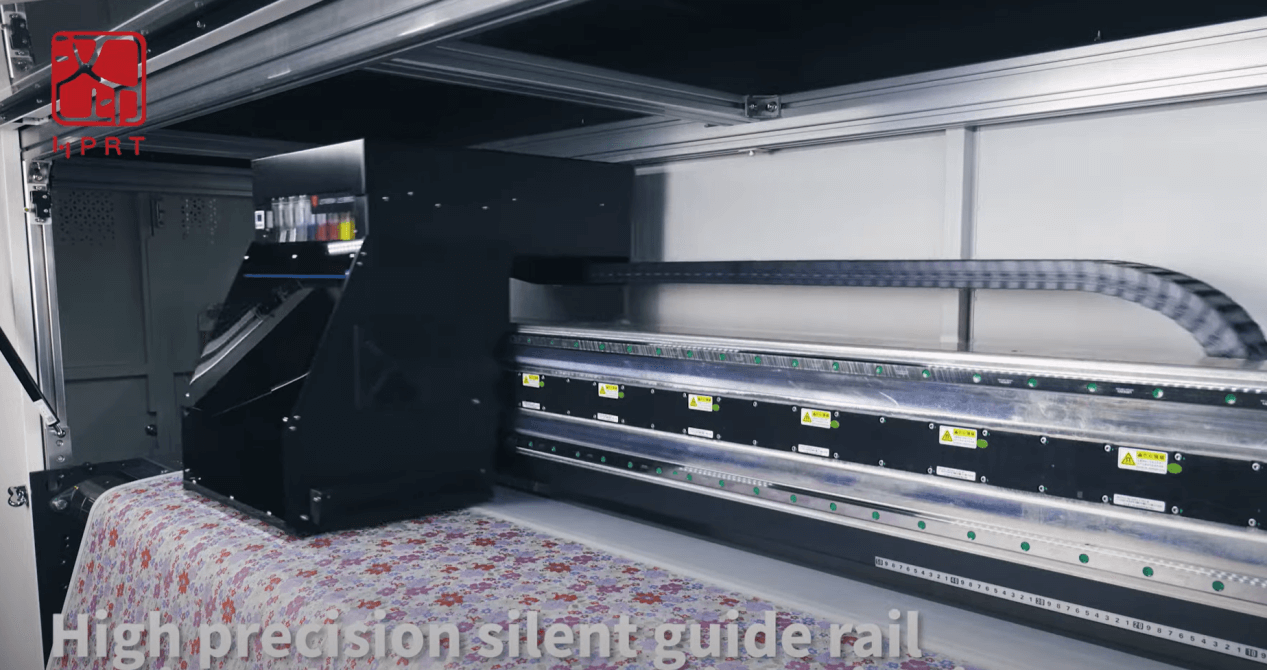

- ●Large-Format Industrial Inkjet Printers: Widely used in corrugated packaging, product boxes, and labeling.

- ●Industrial Direct-to-Fabric Inkjet Printers: Used in textiles, apparel customization, and personalized fabric printing.

Pros:

- ✓ Excellent photo and graphic quality, especially for color prints

- ✓ Works with many media types: plain paper, photo paper, cards, even fabrics

- ✓ Compact designs for home or small office use

Cons:

- ✕ Ink cartridges can be expensive and run out quickly

- ✕ Slower for high-volume printing compared to laser printers

- ✕ Prints may smudge if not handled carefully right after printing

Laser Printers

The first commercial laser printer, the IBM 3800, appeared in 1976 — but it was the launch of the HP LaserJet in 1984 that brought the technology to offices worldwide. With their speed, precision, and low running costs, laser printers soon became the business standard.

How Laser Printer Works:

A laser beam projects an image of the page onto a rotating drum coated with a photosensitive material. The charged areas attract powdered toner, which is then transferred to paper and fused with heat and pressure. The process is fast, efficient, and well-suited for handling large print volumes.

Laser Printer Types and Uses:

Home Use

- ●Small Laser Printers: Black-and-white or color models, great for students and everyday home documents.

Business Use

- ●Office Laser Printers: High-speed printing for large document batches.

- ●Multifunction Laser Printers (MFPs): Combine printing, copying, scanning, and faxing to meet diverse office needs.

Industrial Use

- ●Production Laser Printers: Ultra-fast, high-volume output for publishing and quick-turnaround print shops.

- ●Large-Format Laser Printers: Handle A3 and large-format output, popular in design, advertising, and precision printing.

Pros:

- ✓ Very fast for large print jobs

- ✓ Crisp text and consistent output, high-end models reach up to 1200 dpi resolution

- ✓ Lower cost per page than inkjets for bulk printing, ideal for businesses and schools

- ✓ Low maintenance, no risk of printhead clogging

Cons:

- ✕ High replacement cost for color toner; larger footprint than most inkjets

- ✕ Not ideal for high-end photo printing

- ✕ Higher upfront cost

LED Printers

LED printers emerged in the late 1980s, pioneered by companies like OKI. They aimed to simplify the laser printing process by replacing moving laser mirrors with fixed LED arrays.

How LED Printer Works:

Instead of a laser beam scanning across the drum, an LED printer uses a row of light-emitting diodes to expose the image in one pass. This reduces mechanical complexity, potentially improving durability.

Applications:

LED printers mainly target the business office market, often found in small offices and schools. Most come as desktop or multifunction models. They run faster and last longer than inkjets, and are simpler and more compact than lasers, but they trail in image quality and market adoption.

Pros:

- ✓ Fewer moving parts, meaning less maintenance

- ✓ Often smaller and lighter than laser printers

- ✓ Fast and reliable for text-heavy documents

Cons:

- ✕ Fewer model options on the market

- ✕ Print quality for detailed graphics may trail top-tier laser printers

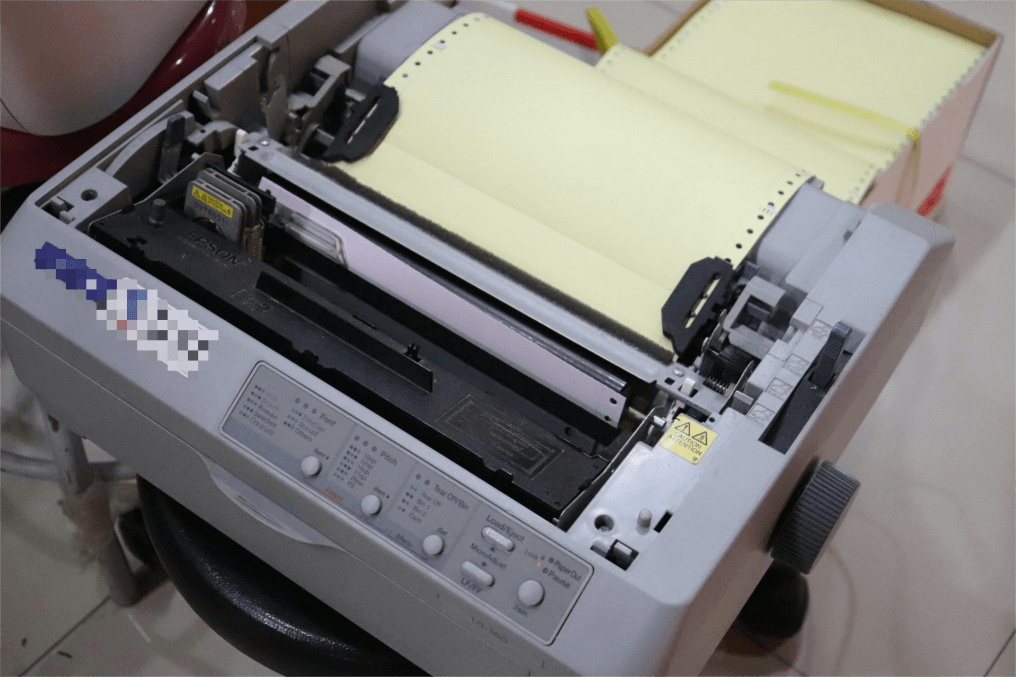

Dot Matrix Printers

In the 1970s and 1980s, dot matrix printers were the workhorses of offices. Even today, they still serve in niches where multi-part forms and rugged reliability matter.

How Dot Matrix Printer Works:

A print head with tiny pins strikes an ink ribbon, making dots that form letters or graphics. Because it's an impact method, it can print through carbon copies.

Applications:

Today, dot matrix printers have been replaced by laser and inkjet printers for everyday documents, and even in receipts by thermal printers. Still, they hold value in sectors like banking, finance, logistics, and manufacturing. Though noisy and slow, they excel at multi-part form printing and produce records that last without fading.

Pros:

- ✓ Can print on multi-part forms in a single pass

- ✓ Works in dusty, hot, or otherwise tough environments

- ✓ Extremely low running costs

Cons:

- ✕ Noisy and relatively slow

- ✕ Low resolution with limited graphics capability

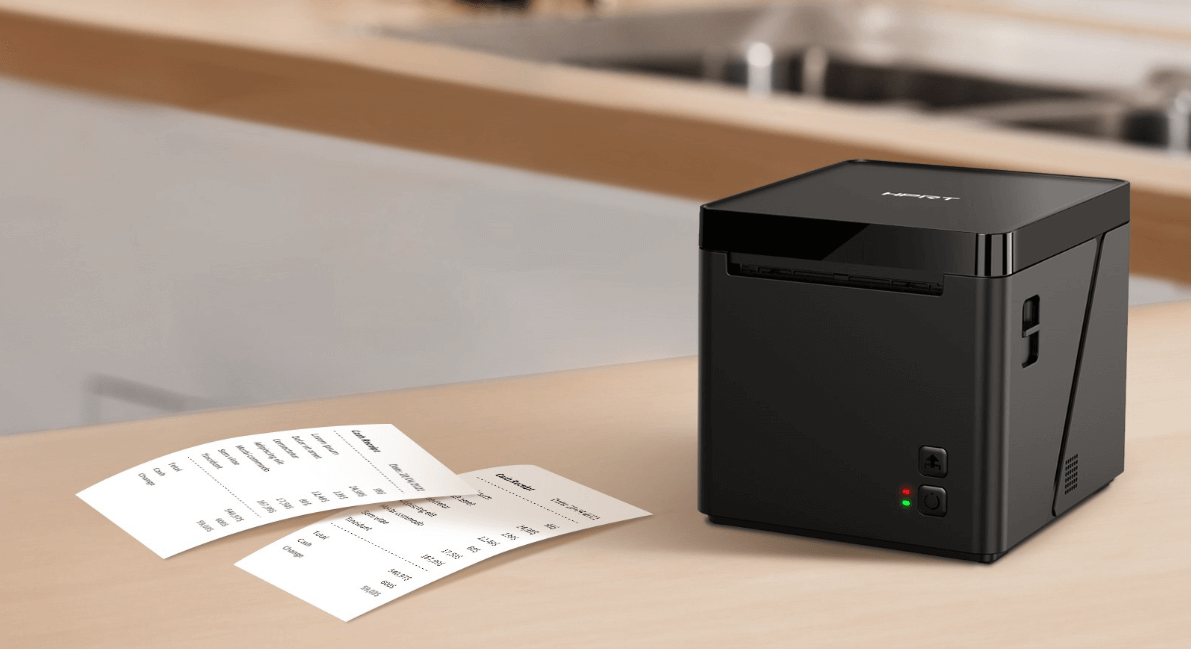

Thermal Printers

Thermal printing started in the 1960s with early fax machines. It evolved into today's compact label printers, receipt printers, and portable photo units. Quiet, fast, and ink-free, it has become the go-to choice for receipts and labels in retail, logistics, and food service.

How Thermal Printer Works:

A heated print head activates the coating on thermal paper or labels, creating text and images. Modern ZINK printers use embedded dye crystals that change color when heated to deliver full-color prints.

Thermal Printer Types and Uses:

Home Use

- ●Label Makers: Great for study, office organization, and labeling household items.

- ●ZINK Photo Printers / Instant Cameras: Print photos on the go and capture memories instantly.

- ●Portable A4 Thermal Printers: Handy for students and mobile office work.

Business Use

- ●POS Receipt Printers, Kitchen Order Printers, Kiosk Printers: Common in retail checkout, restaurant kitchens, and self-service kiosks in banks, hospitals, and cinemas.

- ●Shipping Label Printers, Retail Tag Printers, wristband Printers: Mainly applied in printing waybill, retail price tags, and ID wristbands for hospitals or events.

Industrial Use

- ●Industrial Thermal Label Printers: Built for heavy-duty tasks like warehouse labels, logistics tracking, and temporary tags in manufacturing.

Best Receipt Printers for Small Businesses 2025

Read more →Best Shipping Label Printer in 2025

Read more →Best Travel Printers 2025

Read more →Pros:

- ✓ Quiet, fast, and compact

- ✓ No liquid ink — less mess and maintenance

- ✓ Great for labels, receipts, barcodes

Cons:

- ✕ Direct thermal prints can fade over time

- ✕ Limited media compatibility without using transfer ribbons

- ✕ Mostly suited for specific tasks, not general office documents

Thermal Transfer Printers

Thermal transfer printing became popular in the 1980s for producing durable labels for industrial use. The best thing is that the printed text, barcodes, and graphics stay clear and readable for a long time—even in tough environments like factories, warehouses, or hospitals. They don't fade or wear off easily.

How Thermal Transfer Printer Works:

The print head heats a ribbon coated with wax, resin, or a mix, transferring the ink to the media like paper, film, or synthetic labels. The result is a long-lasting print that can handle tough environments.

Thermal Transfer Printer Types and Uses:

Business Use

- ●Wash care label printers, hangtag printers, jewelry label printers, cable label printers

- ●Warehouse barcode printers, food label printers, asset label printers

- ●Pharmaceutical and test tube label printers

Industrial Use

- ●Industrial-grade label printers: Outdoor weatherproof labels, machinery and parts labeling

- ●PCB label printers: Electronic component traceability

- ●TTO (Thermal Transfer Overprinters): Batch codes and expiry dates for food, beverage, and pharmaceutical packaging

Top Amazon FBA Label Printer for E-commerce Sellers

Read more →Best Asset Label Printer for Asset Tracking and Industrial Management

Read more →Pros:

- ✓ Highly durable prints

- ✓ Works on a wide range of materials, including plastics and synthetics

- ✓ Resistant to chemicals, heat, and moisture

Cons:

- ✕ Requires ribbon replacement

- ✕ Slower than thermal printing method

- ✕ Not designed for high-quality photographic output

Dye-Sublimation Printers

Dye-sublimation technology first gained traction in photo printing in the 1990s, and later became a favourite for textile printing and personalized gift customization. It prints bright, full-color images with smooth shading—almost like traditional photo prints. That's why it's so popular in both photography and textile printing.

How Dye-Sublimation Printer Works:

Solid dye on a ribbon is heated until it turns into gas, bonding with the print surface. In textiles, the image is first printed on transfer paper, then heat-pressed onto fabric. In photo printers, the dye is transferred directly onto coated paper.

Dye-Sublimation Printer Types and Uses:

Home Use

- ●Dye-sublimation Photo printers: For home and personal photo printing, offering high-quality prints.

Business Use

- ●Desktop dye-sublimation printers: Used for ID photo printing and personalized gifts (mugs, phone cases, T-shirts).

- ●Small-format dye-sublimation printers: For studios and ad agencies producing small batches of fabrics or flags.

Industrial Use

- ●Industrial roll-to-roll sublimation printers: For sportswear, home textiles (curtains, sofas), advertising banners, and trade show backdrops.

Pros:

- ✓ Continuous tone printing for smooth, lifelike photos

- ✓ Vivid colors with long-lasting, fade-resistant, and smudge-proof images

- ✓ Ideal for high-quality full-color images and textile printing

Cons:

- ✕ Requires compatible media

- ✕ Slower than some high-volume printing methods

- ✕ Higher cost for large-volume printing due to expensive consumables

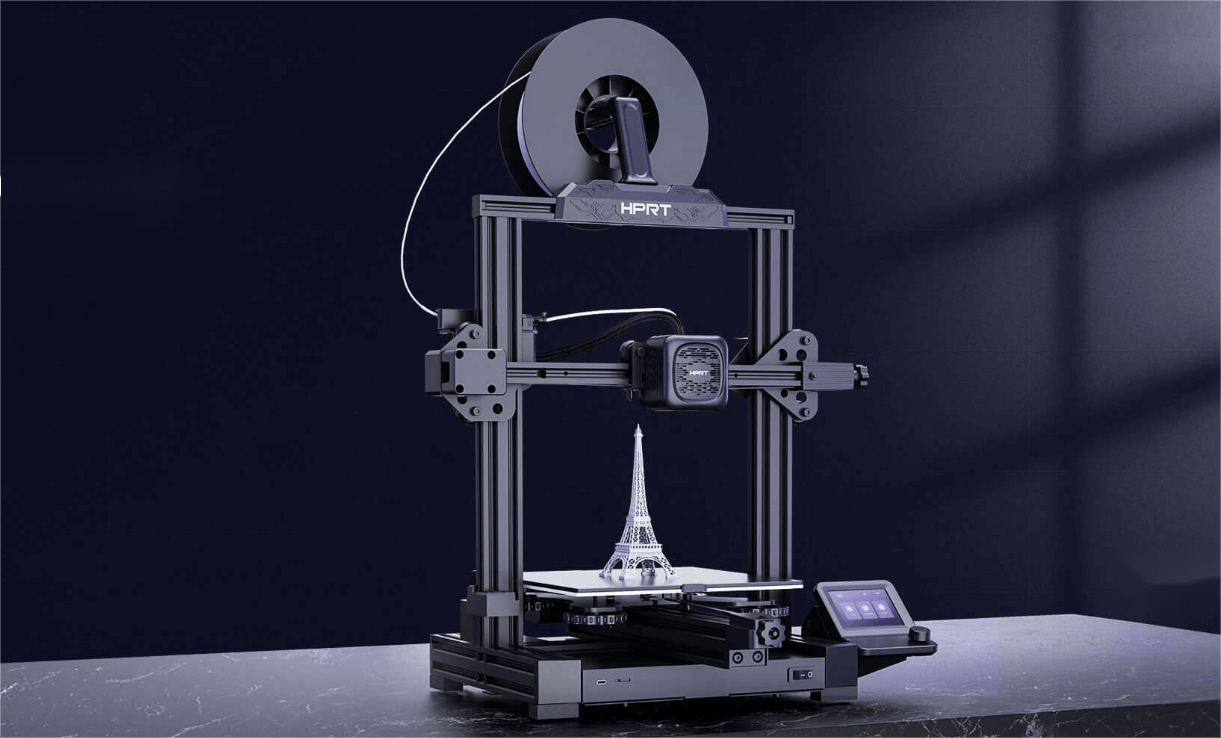

3D Printers

3D printing began in the 1980s with stereolithography (SLA). In recent decades, it has since evolved from prototyping to mainstream use in aerospace, medical devices, automotive, architecture, and education. Its core value lies in on-demand manufacturing and design freedom, enabling complex structures that traditional methods can't achieve.

How 3D Printer Works:

A 3D printer builds objects layer by layer from a digital model. Common processes include:

- ●Fused Deposition Modeling (FDM): Melts and extrudes plastic filament to form layers.

- ●SLA / LCD / DLP: Uses UV light or a projector to cure liquid resin.

- ●Selective Laser Sintering / Multi Jet Fusion (SLS / MJF): Fuses or binds layers of plastic powder with a laser or binding agent.

- ●Selective Laser Melting / Direct Metal Laser Sintering (SLM / DMLS): Uses a high-energy laser to melt metal powder into solid, durable parts.

3D Printer Types and Uses:

Home Use

- ●Desktop FDM Printers: For education, hobbyists, and model making.

Business Use

- ●Desktop Resin Printers: Jewelry prototyping, dental models, and fine crafts.

- ●Commercial FDM Printers: Product prototypes and custom parts.

Industrial Use

- ●Industrial SLA/SLS Printers: Automotive, medical, molds, and architectural design.

- ●Metal 3D Printers (SLM/DMLS): Aerospace, medical implants, and advanced manufacturing.

Pros:

- ✓ Can create complex shapes impossible with traditional manufacturing

- ✓ High design flexibility with rapid iterations, reducing product development cycles

- ✓ Enables rapid prototyping and on-demand production

Cons:

- ✕ Low efficiency for mass production, far less scalable than injection molding for high-throughput manufacturing

- ✕ Material limitations: fewer choices, with lower strength, heat resistance, and impact performance than injection molding or CNC machining

- ✕ Parts often need post-processing due to rough surfaces

- ✕ Higher costs for materials and equipment

Wrap-Up

Printers can do a lot today—from homework and photos to shipping labels and 3D parts. Each type has its ups and downs, so the best one comes down to what you need. Know the pros and cons, pick smart, and you'll save time, money, and hassle.