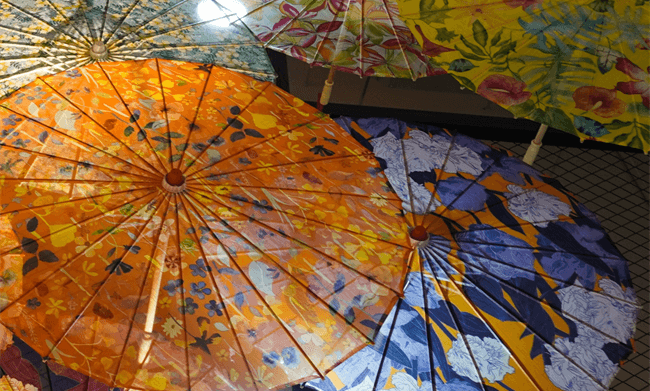

Custom printed umbrellas are making waves as trendy promotional items and unique fashion statements. With advancements in digital printing and sublimation techniques, creating personalized umbrellas has become more accessible and appealing.

This article explores the intricacies of sublimation umbrella printing, highlighting its benefits, applications, and a step-by-step guide to achieving impeccable results.

The Needs of Custom Umbrella Printing

Custom umbrella printing has become increasingly popular for both personal use and commercial marketing.

Consumers are looking for uniquely designed umbrellas that reflect their style and taste, whether it's vibrant colors, creative patterns, or niche aesthetics like anime-themed umbrellas or gradient artistic prints.

For businesses, personalized umbrellas such as market and patio umbrellas are effective mobile advertising tools, featuring custom logos and creative branding elements to enhance visibility and brand recognition.

Why Choose Dye Sublimation on Umbrellas?

Most umbrellas use polyester canopies for its durability and versatility. While screen printing remains cost-effective for basic, high-volume runs, it can’t handle intricate patterns, gradients, or small batches. Digital printing—especially dye sublimation on polyester—unlocks full-color, detailed designs with ease.

Top Benefits of Sublimation Printing

Unlimited Customization

Allows for full-panel designs with intricate details, complex gradients, and patterns without color limitations.

Soft Feel

Sublimation doesn't add a thick ink layer, keeping the fabric soft, flexible, and breathable.

Exceptional Durability

Prints resist fading, wear, and UV exposure, eliminating issues like cracking or peeling.

Quick Turnaround

No plate-making required, enabling fast turnaround for urgent orders and small-batch printing.

Eco-Friendly Process

Minimizes energy consumption, dye usage, and noise, resulting in a sustainable production method.

Today, digital printing on umbrellas has gained significant market traction, widely used for branded promotional umbrellas, artistic designs, anime-themed styles, and cultural creative products. It is particularly popular in high-end umbrella customization.

How to Sublimate an Umbrella

The sublimation process involves several precise steps to ensure a flawless final product.

-

1.

Prepare the Design

Create a high-resolution digital design using graphic software, ensuring it meets all specifications for clarity and color accuracy.

-

2.

Print on Transfer Paper

Use a professional dye sub printer to transfer the design onto specialized paper, ensuring perfect color representation.

-

3.

Heat Press

Apply the transfer paper to the umbrella fabric using a heat press at the correct temperature and duration to infuse the dye into the fibers.

-

4.

Post-Processing & Quality Control

Rinse with cold water to remove excess dye, then conduct a thorough inspection for print alignment, color fastness, and overall durability.

Purchasing the Right Umbrella Printer

Choosing the right equipment is critical. Manufacturers should consider these key factors to match a printer to their specific needs.

1. Production Requirements

- Batch Size (small vs. large-scale)

- Design Complexity & Resolution

- Material Compatibility (polyester, nylon, etc.)

2. Equipment Performance

Analyze print resolution, speed, color accuracy, and automation capabilities.

3. Cost-Effectiveness

- Balance initial investment with long-term ROI.

- Consider consumable costs and maintenance.

4. Software & Support

Look for integrated software and reliable after-sales service and technical support.

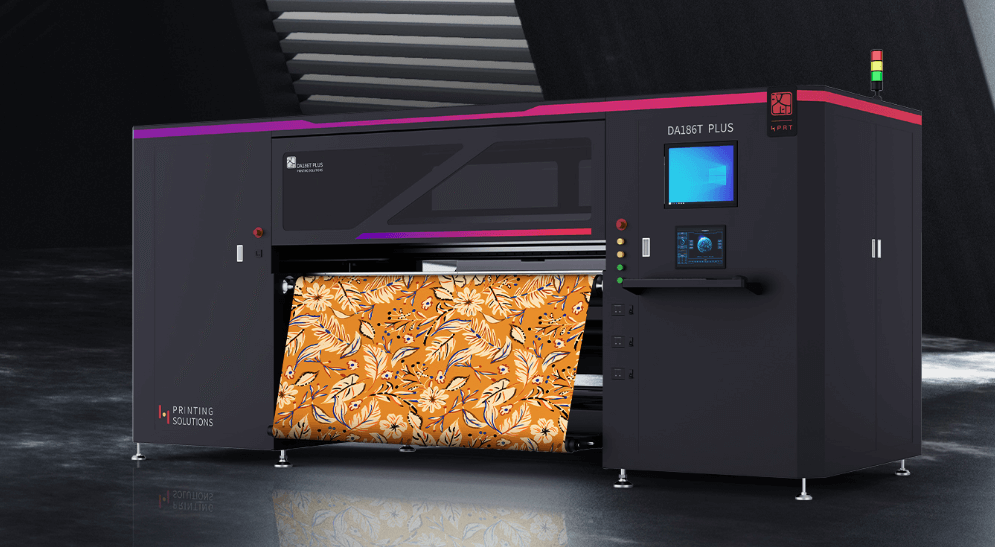

HPRT's Industrial Sublimation Printers

HPRT offers high-performance industrial sublimation printers with up to 1200 DPI resolution and a capacity of 1080 square meters per hour.

Choose from 4-, 6- or more advanced color modes to achieve vivid gradients and sharp details on polyester and blended fabrics. Final prints resist water, abrasion, and UV—perfect for:

● Custom Umbrellas & Parasols: Premium promotional and fashion designs

● Home Textiles: Precision prints for curtains, bedding, and table linens

● Sportswear: Breathable, colorfast graphics on performance apparel

HPRT digital textile printers pair peak performance with rock-solid reliability and user-friendly design. Smart maintenance systems—including self-cleaning printheads and humidity-control modules—keep output consistent and downtime to a minimum.

Deployed from India to Bangladesh, our fabric printers earn top marks for dependable results—and with 24/7 support plus rapid spare-parts delivery, installation and production stay smooth.

Explore Our PrintersFrequently Asked Questions

Q1: Can you sublimate on an umbrella?

A: Yes, sublimation printing is ideal for umbrellas, especially those made of polyester or polyester-blend fabrics. The process involves transferring dye into the fabric using heat, resulting in vibrant, full-color designs that are durable and weather-resistant.

Q2: Is sublimation weather proof?

A: Absolutely. Sublimated prints are highly weatherproof, making them perfect for outdoor use. The dye bonds with the fabric fibers, ensuring resistance to rain, UV rays, and fading, even after prolonged exposure.

Q3: What Cannot be sublimated?

A: Sublimation works best on polyester or polymer-coated materials. It is not suitable for natural fibers like cotton or materials without a polyester coating, as the dye requires synthetic fibers to bond effectively.

Q4: Does sublimation fade in sunlight?

A: No, sublimation prints are UV-resistant and designed to withstand sunlight. Unlike traditional printing methods, sublimated designs remain vibrant and fade-free, even with frequent outdoor use.