Why Is Color Difference So Troublesome?

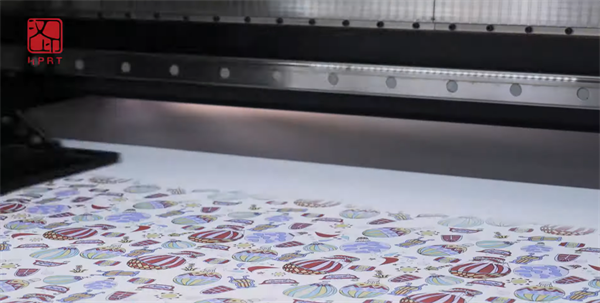

In today’s textile manufacturing industry, digital textile printers are widely used in clothing fabrics, home décor, sportswear, and many other fields. Renowned for their high precision, efficiency, and eco-friendliness, they enable rapid output of complex patterns and multilayer colors—marking a major shift from traditional printing to digital production.

However, in real-world production, color difference (color inconsistency or deviation) still frequently occurs. Common issues include:

- ●The printed result doesn’t match the design color on screen;

- ●The same style shows different shades across production batches;

- ●The output from different printers varies in tone or brightness.

As a professional digital textile printer manufacturer, we’ll explain the technical principles behind these issues and share a systematic color management approach—from theory to practice—to help you achieve consistent and accurate printing colors.

Where Does Color Difference Come From? — Understanding How Colors Are Formed

Before we dive into the reasons for color variation, let’s understand one key concept: the color you see on a screen and the color printed on fabric come from two entirely different systems.

Screen Colors (RGB – Additive Color Model)

Computer and phone screens use Red (R), Green (G), and Blue (B) light. The more light you add, the brighter the color, and when combined fully, they create white. RGB has a wide color gamut, especially for high-saturation colors.

Printed Colors (CMYK – Subtractive Color Model)

Fabric doesn’t emit light. It absorbs parts of the light spectrum through ink and reflects the rest. The more ink you add, the darker the color becomes. The CMYK (Cyan, Magenta, Yellow, Black) color gamut is much smaller than RGB.

Therefore, it’s physically inevitable that colors on screen look brighter and more vivid than printed ones—one of the basic causes of color difference in textile printing.

Main Causes of Color Difference in Digital Textile Printing and Solutions

Color difference isn’t caused by a single factor—it’s the result of multiple interacting variables. Below are the most common and critical ones.

1. Display and Design File Settings

Not all monitors are created equal. A designer might work on a high-gamut monitor, while the production computer uses a standard office screen. As a result, the same image may display differently.

Moreover, inconsistent color spaces (sRGB, Adobe RGB, CMYK) and lack of coordination between design files and RIP software can easily cause printing color deviation.

Solutions:

- ● Use hardware-calibrated professional monitors and unify color space settings.

- ● Create and apply monitor ICC Profiles using tools like X-Rite or Datacolor.

- ● Conduct soft proofing in design software to preview color output using the printer’s ICC profile.

2. Environmental Factors: Temperature and Humidity

Environmental conditions directly affect ink performance.

When the air is too dry, static electricity builds up on fabrics, disturbing ink droplet trajectories and causing banding or uneven colors.

Extreme temperatures alter ink viscosity and surface tension, affecting droplet formation and density, leading to light or dark patches.

Recommendation:

Maintain the production environment at 20–25°C and 40–60% RH to ensure stable ink ejection and color consistency.

3. Fabric and Pretreatment Differences

Even under identical printing processes, different fabric batches can produce varying results—because fabrics are never 100% identical. Factors influencing color variation include:

- Fabric whiteness;

- Uniformity of coating or pretreatment;

- Presence of optical brightening agents (OBA);

- Fiber structure and ink absorption.

These affect how fabrics reflect light, leading to visible shade variation between batches.

Solution:

Use a spectrophotometer to measure fabric whiteness and characteristics, and whenever possible, use fabric from the same batch for bulk production.

4. Fabric Printer, Ink, and RIP Software Variability

Even two printers of the same model can’t guarantee identical color output. Slight differences in printheads, ink batches, or color curve settings can create systematic shade variation.

Uneven nozzle performance or stepper calibration errors can cause banding, a visible horizontal pattern of light and dark stripes.

Among all factors, the RIP software (Raster Image Processor) plays the most critical role in color management in textile printing. It interprets image data, allocates ink, and applies ICC profiles. Different RIP settings, rendering intents, or ICC versions can cause noticeable output variation.

Solutions:

- Build a unique ICC profile for each “printer + ink + fabric” combination.

- Use certified or original inks with stable formulation and batch consistency.

- Regularly calibrate equipment and update ICC and RIP settings for synchronized color management.

5. Post-Processing Effects

Sometimes the print looks perfect at first but changes color after steaming, curing, or washing. This happens because post-treatment parameters—temperature, duration, and process method—affect color hue and density.

For instance, overheating may cause hue shifts. Incomplete washing leads to dullness or fading.

Solutions:

- Standardize post-finishing parameters (temperature, duration, washing).

- Include post-treatment in the color management workflow.

- Treat post-processing consistency as equally important as printing consistency.

How to Reduce Color Difference and Improve Color Consistency

In many print shops, color management is the most neglected yet most crucial step.

To achieve digital textile printing color accuracy, it’s essential to implement a scientific and standardized workflow. Below is a practical checklist to help you.

Below is a practical checklist to help you reduce color difference and enhance color consistency step by step:

Unify Color Standards

Base all design and sampling on Pantone color codes, avoiding subjective descriptions.

Use a Consistent Color Mode

Always design in CMYK mode to ensure consistent color conversion.

Sample Before Mass Production

Always perform a strike-off (test print) before large-scale printing—spending a little upfront saves a lot later.

Control Material Consistency

Use the same fabric batch whenever possible, measure whiteness and ink absorption, and keep ink brands/batches stable.

Regular Equipment Calibration

Update ICC profiles every 3–6 months, calibrate printers and RIP software, and maintain consistent output.

Final Thoughts

Color difference is not unavoidable—it can be scientifically managed. The key is to ensure that every stage—from design and proofing to final production—follows unified standards and data-driven processes.

Hanin’s digital textile printing machines, equipped with advanced RIP software color management, precisely interpret color data and automatically optimize ICC curves. This enables textile manufacturers to achieve stable output, higher color consistency, and fewer reworks.

If you’re looking for a more efficient and controllable digital textile printing solution, contact the Hanin team for professional technical support and customized consultation.