Guillotine Cutter vs Hobbing Cutter: Which Is the Right Cutting Solution for Your Barcode Printer?

Barcode printers often come equipped with a range of high-performance accessories specifically designed for quick and accurate label cutting. Among these, the guillotine cutter module stands out as a popular optional feature for immediate and precise label trimming. Another, less commonly known accessory is the hobbing cutter.

Choosing the right cutting module for your barcode printer can significantly impact the efficiency and accuracy of your operations. But how do you decide between a guillotine cutter and a hobbing cutter? This article aims to clarify the distinctions between these two types of cutter modules and provide a critical comparison of their respective advantages and applications.

Guillotine Cutter

1. Working Principle

In barcode printers, the working principle of the paper guillotine cutter module is straightforward. Upon receiving a command from the printer, a specialized mechanical arm descends rapidly to cut labels or other materials accurately. This operation is supported by highly accurate sensors and a sophisticated control system, ensuring each cut meets predetermined quality standards.

2. Applications

The guillotine cutter has a wide range of applications in the field of barcode printing, including sectors such as logistics tracking, product identification, healthcare, and retail.

For instance, it is commonly used for creating goods labels in logistics, fixed asset labels, and equipment labels. Its primary use cases involve durable materials like plastic or paper labels, which maintain their integrity during the cutting process, thus ensuring precision and durability.

HPRT’s research and development team, after extensive research and practical application, has innovated a unique feature known as the "non-retracting cutter."

Unlike conventional barcode printers, which follow a complete forward and backward motion during the cutting process, this technology eliminates the backward movement. This not only substantially enhances efficiency but also eliminates friction issues between the paper and the carbon ribbon during the retraction process. This means there won’t be any black marks on the label at the print head.

The "non-retracting cutter" technology is not limited to desktop barcode printers; it also extends to industrial barcode printers. For instance, the iX4L 4-inch industrial barcode printer, which features both "first label no waste" and "non-retracting cutter" technologies, significantly streamlines the ticket printing process for Chinese railway management departments.

Hobbing Cutter

1. Working Principle

The hobbing cutter offers a different approach compared to the traditional cutter module. Rather than employing vertical pressure to cut materials, it uses a rotational method, making it particularly suitable for softer, more flexible materials and minimizing the risk of material deformation.

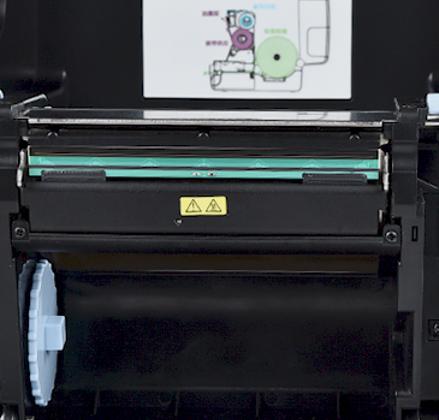

The design of the hobbing cutter typically features a circular blade fixed to a rotating axis. As labels pass through the printer, this blade spins at a high velocity, cleanly cutting the labels.

2. Applications

This hobbing cutter is especially advantageous for labels made of specific materials like wash care labels, fabric labels, silver labels, and vinyl. However, it’s important to note that the hobbing cutter is generally designed to be used with high-speed barcode printers. In the garment industry, wash care labels, which often contain critical care and maintenance information, are commonly made of softer materials. Traditional cutters can result in label tearing or distortion, issues that the hobbing cutter effectively circumvents.

Case Study

The iT4X is a high-speed desktop barcode printerboasting a printing speed of 8 inches per second (ips) at a 203 DPI resolution.

Coupled with its specialized rotary cutter attachment, the printer effortlessly handles a variety of label materials including wash care labels, fabric labels, and silver labels. The printer is designed for diverse applications such as fixed asset identification, garment label printing, premium product packaging, and pharmaceutical label printing.

Outfitted with a durable, professional-grade print head, the iT4X promises an extended lifespan, outperforming standard printers in the market. Moreover, its premium cutter module not only ensures seamless paper feeding but also excels in delivering clean, precise cuts.

This 4-inch barcode printer is equipped with a versatile media detection system, featuring both movable reflective and transmissive sensors. This allows it to accurately identify and print on various types of media such as gap labels, black marks, and continuous paper, ensuring fast and precise printing.

It has proven its efficacy across multiple industries—ranging from textiles and food to healthcare and retail—the iT4X has garnered widespread recognition. If you’re in search of a barcode printer that masterfully combines speed with quality, the iT4X emerges as an indisputably trustworthy option.

Selecting the appropriate label-cutting module is vital for maximizing both the efficiency and accuracy of your printing operations. Whether it’s a paper guillotine cutter or a hobbing cutter, each has its own set of advantages and applications. When considering your next barcode or label printer purchase, these optional modules deserve your attention as they can significantly simplify your workflow.