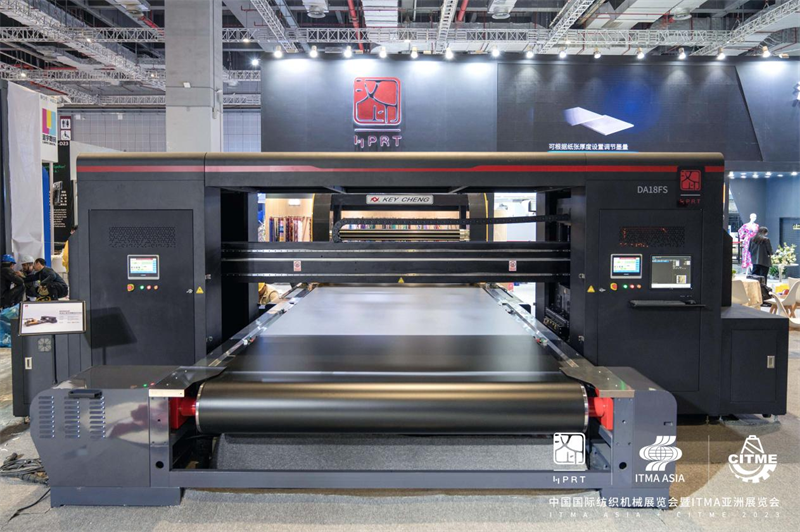

HPRT DA18FS Hybrid: Advanced Hybrid Textile Printer with Inline Pretreatment, Digital Printing, and Flatbed Screening

2023-12-05 18:10

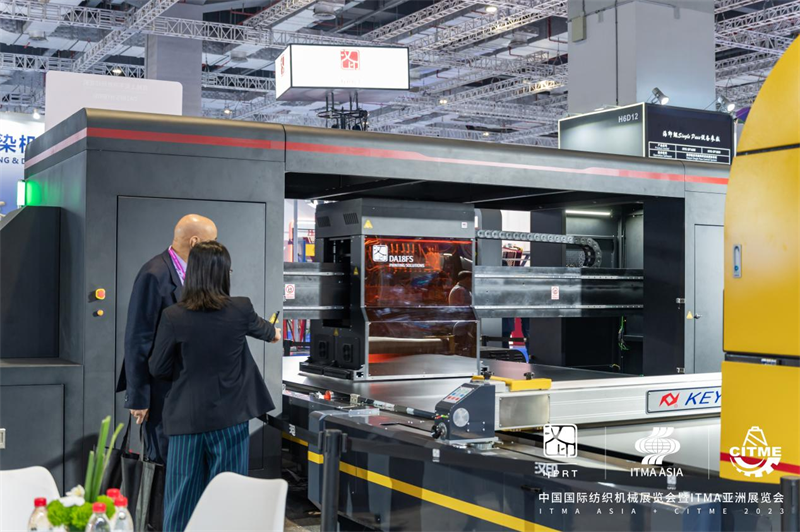

In the digital textile printing, technological breakthroughs and innovations are advancing at an astonishing pace, continually pushing beyond the limitations of traditional printing. Amidst this wave, HPRT’s newly launched DA18FS Hybrid Online Sizing Flatbed Screen+Digital Textile Printer has become a focal point in the industry. Its innovative integration of inline pretreatment and flat screen printing in a unified printing solution was a highlight at the recently concluded ITMA Asia exhibition, attracting keen interest from attendees from various countries.

Below, we delve into the unique features of the DA18FS Hybrid and analyze how it achieves significant breakthroughs in digital textile printing technology.

Integrated Inline Pretreatment and Flat Screen Printing: A Hybrid Digital Textile Printer

1.Inline Pretreatment

Pretreatment has always been a necessary step before digital direct-to-fabric printing, especially for fabrics like cotton, silk, wool, and polyester. Conventional methods involve using rollers, sprays, or immersion to evenly coat the fabric with pretreatment liquid, followed by curing in a dryer.

The HPRT DA18FS Hybrid ingeniously integrates the inline pretreatment module into the digital fabric printer. With its advanced mechanism and efficient circular screen coating, it effortlessly completes fabric pretreatment, significantly simplifying the printing process. Moreover, keeping the fabric moist for subsequent digital printing, this unique "wet-on-wet" technique results in more vibrant and cost-effective prints. The benefits include:

●Increased Production Efficiency: Integrating the pretreatment process into the printing workflow reduces time and labor, while the continuous, smooth, and even coating of the circular screen further enhances overall productivity.

●Improved Ink Penetration: The wet-on-wet printing process keeps the fabric moist throughout printing, allowing for better ink penetration into the fibers, enhancing color saturation and dye uptake for more natural color blending.

●Reduced Factory Space Requirements: Inline pretreatment significantly reduces the need for additional machinery, like separate pretreatment equipment, leading to a more compact and efficient production layout.

●Eco-Friendly and Cost-Effective: This method effectively reduces ink consumption by 30% and also lowers water and energy usage; reducing additional equipment needs also means lower overall production costs.

2.Flat Screen Printing

Despite digital printing’s superiority in fabric compatibility, efficiency, and flexibility over traditional silk screen printing, the latter still holds a place in certain specialized areas.

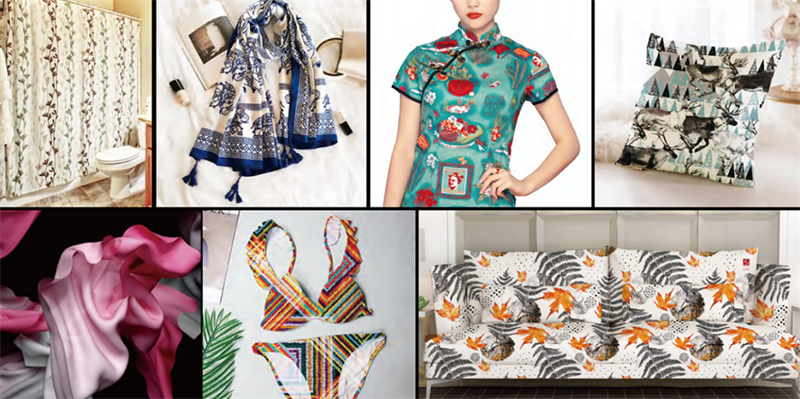

The unique advantage of silk screen printing lies not in color or detailed graphics, but in its ability to use special printing pastes that produce effects like gold, silver, pearlescent, crackling, hot stamping flocking, etc. These are often used in high-end fashion, scarves, and home decor items like curtains and cushions.

The HPRT DA18FS Hybrid digital fabric printer innovatively incorporates flat bed screening technology into the machine, effectively compensating for digital printing’s shortcomings in applying special materials like gold and silver powder. This hybrid printing mode combines traditional craftsmanship with modern technology, creating a more versatile and efficient digital textile printing machine .

Five Key Advantages of the DA18FS Hybrid Digital Textile Printer

Designing a hybrid digital textile printer that effectively integrates different printing modules is a challenge. Through continuous experimentation and integration by HPRT’s R&D team, the DA18FS Hybrid achieves stable, precise, and high-speed hybrid digital textile printing. Let’s focus on its five core advantages:

1.Unique Tension-Free Fabric Feeding Mechanism

This digital direct-to-fabric printer features a newly developed continuous, tension-free fabric feeding device. This design allows uninterrupted fabric feeding, automatically monitoring and adjusting the running speed to synchronize with the dryer. The tension-free feeding technology is suitable for various fabrics, including cotton, silk, polyester, and blends.

2.Intelligent Pattern Matching Automatic Detection System

The DA18FS Hybrid is equipped with a high-precision positioning and detection system, automatically adjusting the circular screen coating position to ensure alignment with the digital print pattern, effectively preventing color overlap or staining on unpatterned fabric areas.

3.High-Speed Printing

This industrial digital textile printer uses 64 Kyocera industrial-grade print heads, reaching a maximum speed of 1080㎡/h in 2-pass mode. It’s suitable for coating, reactive, acid, and disperse inks, meeting diverse fabric printing needs.

4.Convenient Flatbed Screen Printing

The DA18FS Hybrid features an integrated industrial design with a streamlined structure, making flatbed screen mounting and dismounting more convenient. Changing different screens requires only visual adjustments, and adding paste is quick and efficient, effectively preventing screen damage.

5.Supporting Professional OEM/ODM Customization

Clothing manufacturers, textile producers, and garment factories can choose specific models of the DA18FS Hybrid industrial digital textile printer based on their needs, such as a combination of circular screen coating and digital printing, or an all-in-one printing solution with inline pretreatment, digital printing, and flat screen printing.

For clients with special requirements, we also offers professional OEM/ODM customization solutions. Recently, HPRT collaborated with a swimwear brand to custom-make a printer with 10 color channels for an ultra-wide color gamut, meeting the client’s refined color printing needs.

This hybrid textile printer, integrating inline pretreatment, digital, and flat screen printing, is not only suitable for various clothing categories, including professional yoga wear, swimwear, and various sports equipment, but also for home applications like exquisite carpets, soft wool blankets, and highly absorbent towels. Its versatility extends to printing flags, umbrellas, and banners, demonstrating the flexibility of this technology.

For those interested in enhancing your digital printing processes, HPRT’s DA18FS Hybrid offers a comprehensive hybrid fabric printing solution that promises to elevate print quality and expand application possibilities across various fields.

Contact HPRT for more information on this innovative product and to explore how it can transform your digital printing capabilities.